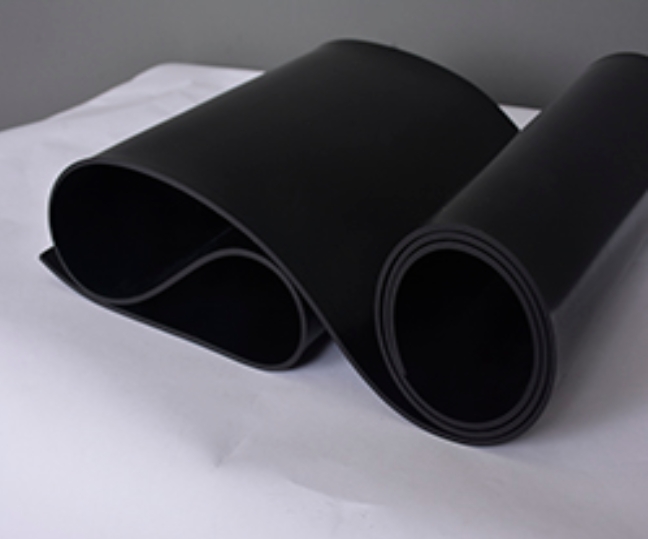

Oil-resistant rubber sheet is one of the most common types of industrial rubber sheets.So,what is the material of oil-resistant rubber sheet?

The oil-resistant properties of rubber sheets are good in nitrile rubber(NBR),hydrogenated nitrile rubber(HNBR),chloroprene rubber(CR),and fluorine rubber(FKM).

One,Nitrile Rubber(NBR)

Nitrile rubber is made by copolymerizing butadiene and acrylonitrile.Nitrile rubber sheets are mainly produced by low-temperature emulsion polymerization.The acrylonitrile content ranges from 18%to 50%.The higher the acrylonitrile content,the better the resistance to petroleum products and hydrocarbon fuels,but the poorer the low-temperature properties.The normal operating temperature range is-25 to 100℃.Nitrile rubber is one of the most commonly used rubbers for oil seals and O-rings.

Nitrile rubber has good resistance to oil,water,solvents,gas tightness,high pressure oil resistance,and excellent adhesion properties.It has good sealing and anti-expansion properties in oil media(such as engine oil,diesel oil,gasoline,lubricating oil).It has good compression resistance,wear resistance,and elongation.

It has good water resistance,gas tightness,and excellent adhesion properties.It is widely used to make various oil-resistant rubber products,such as oil-resistant gaskets,gaskets,sleeves,soft packaging,soft rubber hoses,printing rubber rollers,and cable rubber materials.It is an indispensable elastic material in the automotive,aviation,petroleum,and copying industries.

Two,Hydrogenated Nitrile Rubber(HNBR)

Hydrogenated Nitrile Rubber is made by catalytic hydrogenation of the unsaturated double bond in neoprene rubber,with the main chain becoming a saturated structure but retaining the nitrile group.This makes HNBR retain its excellent oil resistance while having high strength,high tear resistance,good abrasion resistance,excellent adhesion,heat resistance,weather resistance,and chemical stability.It can withstand acids,bases,and salts at high temperatures,and can work in lubricating oil and fuel oil media with corrosive additives.It is one of the most outstanding rubbers in terms of comprehensive performance.

Hydrogenated Nitrile Rubber is currently widely used in the oilfield,automotive industry,etc.It is particularly suitable for producing drill pipe covers for oil and gas wells,valve seal rings,and gaskets for pumps and other rubber parts.The radiation resistance of HNBR is better than that of silicone rubber,fluorine rubber,and polytetrafluoroethylene,and is also suitable for producing various rubber seals for nuclear power plants.

Three.Chloroprene Rubber Sheet(CR)

Chloroprene Rubber Sheet is a multi-purpose elastomer with good overall performance.It not only resists silicone-based lubricating oil,but also has good tensile strength,excellent physical toughness;good heat resistance,ozone resistance,weathering resistance,and heat resistance is better than nitrile rubber sheet,weathering resistance is next to EPDM rubber sheet,does not fear direct sunlight,does not fear violent twisting,does not fear refrigerants,is not afraid of dilute acids,tends to crystallize and harden at low temperatures,storage stability is poor,expands greatly in mineral oil with low benzamine point,general use temperature range is-50~150℃.Chloroprene Rubber Sheet has flame retardancy,does not spontaneously combust,can burn when in contact with flames,and self-extinguishes when away from flames,the oxygen index is 38-41.The oxygen index of a material is 27 or higher is considered a difficult-to-combust material.Any rubber sheet containing sufficient halogen has flame retardancy.The oxygen index is a measure of the material’s combustion performance,and its definition is the lowest volume of oxygen gas required for the candle-like flame to be maintained in a nitrogen-oxygen mixture.Chloroprene Rubber Sheet has a very high oxygen index and is very difficult to burn,second only to fluorine rubber.

Four.Fluorine Rubber Sheet(FKM)

Fluorine Rubber Sheet has the characteristics of oil resistance,high temperature resistance,and chemical corrosion resistance,and the working temperature is-25℃-250℃.

Fluorine rubber is a high-performance rubber with excellent resistance to hydrocarbons,chemicals,oil,and heat.It also has excellent compression resistance,especially at high temperatures.This rubber sheet is widely used in the petroleum industry,aerospace industry,automotive industry,and other corrosive environments.It is suitable for punching various high-oil-resistant,flame-retardant,high-temperature-resistant,and corrosive sealing parts,sealing rings,cylinder membrane linings,and products for use in the aerospace and aviation fields.