The physical and mechanical properties of insulating rubber sheet are good,and it has excellent insulation properties.What is the production process of insulating rubber sheet?

1.The raw rubber needs to be plasticized to improve its plasticity in order to achieve the purpose of adding various required auxiliaries to rubber;

2.The carbon black and various rubber auxiliaries are evenly mixed with rubber by mixing to form rubber compound;

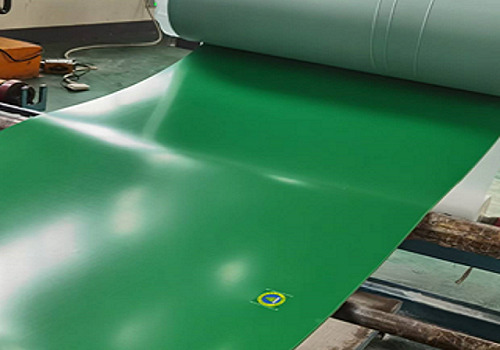

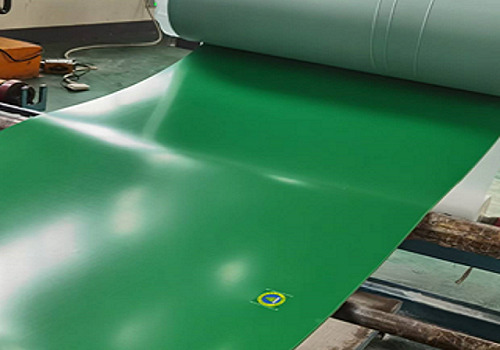

3.The rubber compound is extruded into a certain shape blank,and then combined with the textile material that has been coated with rubber or metal material by pressing to form semi-finished products;

4.The semi-finished products with plasticity are vulcanized into highly elastic products;

5.The high-elastic products produced are inspected,and those that do not meet the requirements must be re-produced;

6.The high-quality insulating rubber sheet is packed and loaded onto trucks.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, Neoprene Rubber Sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with nearly 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.