Nitrile rubber(NBR)is a high-performance elastomer that is widely favored for its excellent oil resistance.Whether in industrial sealing,automotive parts,or food processing equipment,NBR sheets demonstrate outstanding oil resistance.But why is NBR oil-resistant?What is its oil resistance performance like?This article will provide you with a detailed analysis.

1.The Principle of Nitrile Rubber’s Oil Resistance

Nitrile rubber is a high-molecular material copolymerized from acrylonitrile(ACN)and butadiene.Its oil resistance mainly stems from the polar molecular structure of acrylonitrile:

Polar molecular characteristics:The polarity of acrylonitrile enables it to resist the erosion of non-polar oils and solvents.

Cross-linked structure:The molecular chains of nitrile rubber form a stable three-dimensional network structure through vulcanization,further enhancing its oil resistance and mechanical strength.

2.The Performance of Nitrile Rubber’s Oil Resistance

Nitrile rubber sheets exhibit excellent oil resistance in various oils and solvents:

Petroleum-based oils:Such as engine oil,diesel,and lubricating oil,NBR sheets are almost unaffected.

Fuel oils:Suitable for sealing components in gasoline and biodiesel fuel systems.

Greases and lubricants:Stable in the sealing and protection of mechanical equipment.

It should be noted that NBR has poor resistance to polar solvents(such as ketones and esters),so the material selection should be evaluated based on specific working conditions.

3.Key Factors Affecting Oil Resistance

The oil resistance of NBR sheets is influenced by the following factors:

Acrylonitrile content:The higher the acrylonitrile content,the stronger the oil resistance,but the low-temperature performance will decline.

Vulcanization system:An optimized vulcanization process can increase the cross-link density of the rubber,enhancing its oil resistance.

Additives:The choice of fillers and plasticizers also affects its oil resistance performance.

4.Application Areas of Nitrile Rubber’s Oil Resistance

With its excellent oil resistance,NBR sheets are widely used in the following fields:

Automotive industry:For fuel system seals,oil pan gaskets,hydraulic system seals,etc.

Mechanical equipment:As sealing materials for hydraulic presses,pumps,and valves to prevent oil leakage.

Food processing:FDA-certified NBR sheets can be used for sealing in edible oil equipment.

Aerospace:Provides reliable sealing performance in fuel and lubricating oil environments.

Nitrile rubber sheets,with their outstanding oil resistance,have become the preferred material in industrial sealing and protection fields.By understanding its oil resistance principle,performance,and application scenarios,users can better select suitable NBR sheets to meet specific working conditions.If you need an elastic material that is resistant to oil and chemical corrosion,NBR sheets are undoubtedly an ideal choice.

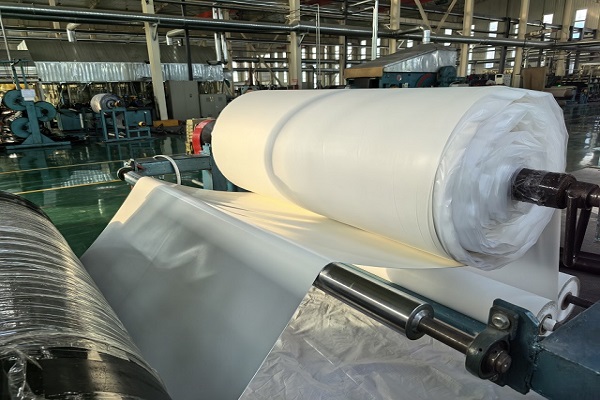

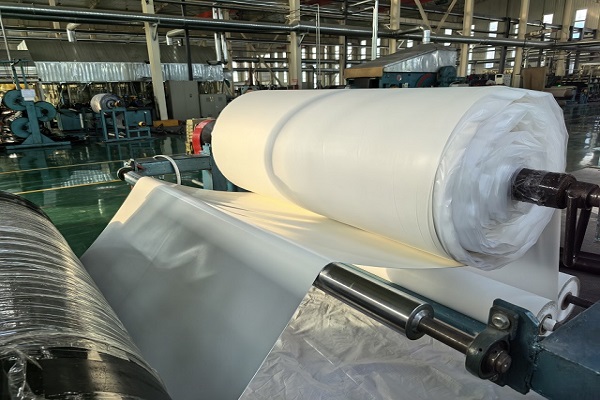

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, Neoprene Rubber Sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.