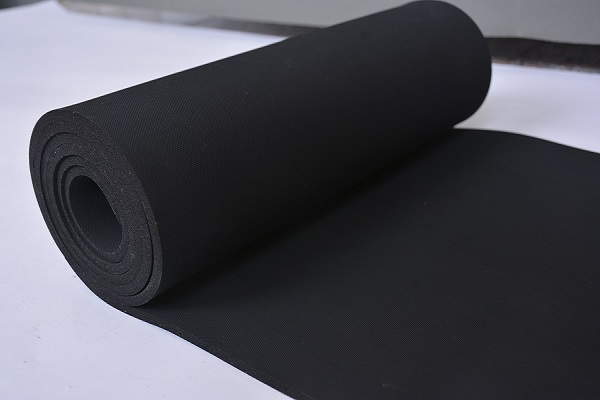

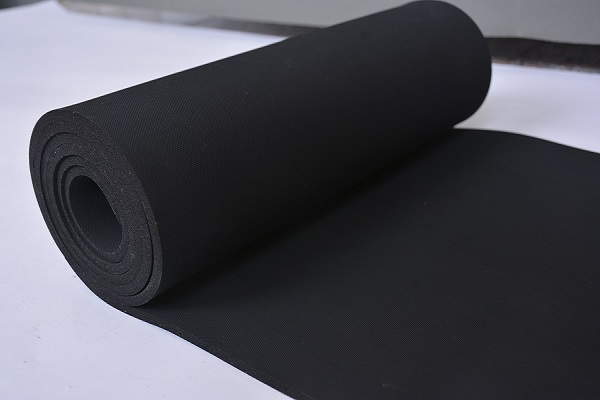

Foam rubber sheets,as a new type of material with features such as light weight,high elasticity,sound insulation,and heat insulation,are widely used in construction,transportation,electronics,and other fields.Their unique physical and chemical properties make them indispensable materials in multiple industries.Hardness standards are one of the important indicators for evaluating the performance of foam rubber sheets and directly affect their application effects and fields.

The hardness of foam rubber sheets is usually expressed by Shore Hardness.Shore Hardness is a common method for measuring the hardness of soft materials and is mainly divided into two types:Shore A and Shore D.Shore A is suitable for softer materials(such as soft rubber)with a hardness range of 0 to 100 degrees;while Shore D is suitable for harder materials(such as hard rubber),also within the range of 0 to 100 degrees.

The Shore Hardness of foam rubber sheets is generally between 8 and 30A,with the specific hardness depending on its density and application requirements.

>send emails to sales@jingdongrubber.com,get a quote now

To ensure that the hardness of foam rubber sheets meets the standards,a series of strict tests and inspections are required.The following are some main inspection items and methods:

**Visual Inspection**

By visually observing the color,texture,and bubbles on the surface of the rubber sheet,it is determined whether there are obvious defects or damages.This is the most basic and simplest inspection method,which can directly screen out products with obvious surface defects.

**Dimension Inspection**

Using measuring tools(such as tape measures and calipers)to measure the length,width,and thickness of the rubber sheet to confirm that it meets the specified size requirements.The accuracy of dimensions is very important for subsequent applications,especially in precision manufacturing and engineering.

**Hardness Testing**

Using a durometer to test the hardness of the rubber sheet surface.This equipment can accurately measure the hardness value of the material and determine whether it meets the predetermined hardness standard.Hardness testing not only reflects the flexibility of the material but also indirectly reflects its wear resistance and compressive strength.

**Tensile Strength Testing**

Using a universal tensile testing machine to conduct tensile tests on the rubber sheet to determine its tensile strength and elongation performance.This test can evaluate the deformation degree and recovery ability of the material under external force,thereby judging its reliability in practical applications.

**Chemical Composition Analysis**

Using chemical analysis instruments to analyze the composition of rubber sheet samples to detect whether they contain harmful substances or toxic elements that exceed the standard.Chemical composition analysis ensures the safety and environmental friendliness of the product and is an indispensable part of modern material testing.

The hardness standard of foam rubber sheets is an important basis for ensuring their performance and quality.Through strict testing and scientific management,we can produce high-quality foam rubber sheets that meet the standards,providing reliable material support for various industries.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.