In industrial production environments,industrial rubber sheets play an indispensable role.They not only provide reliable sealing and protection for various equipment but also have a certain impact on production efficiency and the quality of the working environment.However,to ensure that industrial rubber sheets maintain good performance and condition over the long term,correct cleaning and maintenance techniques are crucial.

During daily use,industrial rubber sheets will inevitably accumulate various dust,oil stains,and other impurities.If these contaminants are not promptly removed,they can not only affect the appearance of the rubber sheets but also have adverse effects on their performance.For instance,oil stains may erode the rubber material,leading to reduced elasticity,increased hardness,and a shortened service life.Moreover,unclean rubber sheet surfaces are prone to bacterial and mold growth,posing a threat to the hygiene of the working environment.

How can industrial rubber sheets be effectively cleaned?

Firstly,basic cleaning is essential.Use a soft-bristled brush or vacuum cleaner to carefully remove dust and debris from the surface of the rubber sheets every day.This step,although seemingly simple,lays a solid foundation for subsequent cleaning.During the cleaning process,be careful not to use sharp tools that could scratch the rubber surface.

>send emails to sales@jingdongrubber.com,get a quote now

For stubborn stains such as oil,specialized cleaning agents should be used.When choosing a cleaning agent,ensure it is suitable for rubber materials and will not cause damage.Mix an appropriate amount of the cleaning agent with water according to the recommended ratio,then use a flat mop or cleaning cloth dipped in the cleaning solution to gently wipe the stained areas.During the wiping process,apply moderate pressure to avoid excessive force that could wear down the rubber surface.

In addition to daily cleaning,regular deep cleaning is also necessary.

Generally,deep cleaning can be conducted weekly or monthly depending on the usage frequency and environmental conditions of the rubber sheets.During deep cleaning,first remove any garbage or glue from the surface of the rubber sheets.Then,mix water with wax remover according to the specified ratio and use a low-speed floor polisher or long-handled brush for wax removal.Keep the floor slightly wet during cleaning but avoid excessive moisture that could seep into the ground through walls or cracks.After cleaning,use a mop or water absorber to remove the dirty water,then rinse with clean water,and finally dry with a dry mop.

After cleaning,appropriate maintenance measures can further extend the service life of industrial rubber sheets.

Apply a layer of rubber floor protectant to the surface of the rubber sheets.This protective layer can prevent the formation of stains and scratches.Additionally,avoid prolonged exposure of the rubber sheets to sunlight or harsh conditions such as high temperatures and humidity.During daily use,be cautious to prevent heavy objects from directly hitting the rubber surface to avoid damage.

Correct cleaning and maintenance techniques can keep industrial rubber sheets in good condition,extend their service life,and provide strong support for the production and development of enterprises.

Only by attaching importance to and properly performing the cleaning and maintenance of industrial rubber sheets can their full potential be realized and the smooth operation of industrial production be ensured.

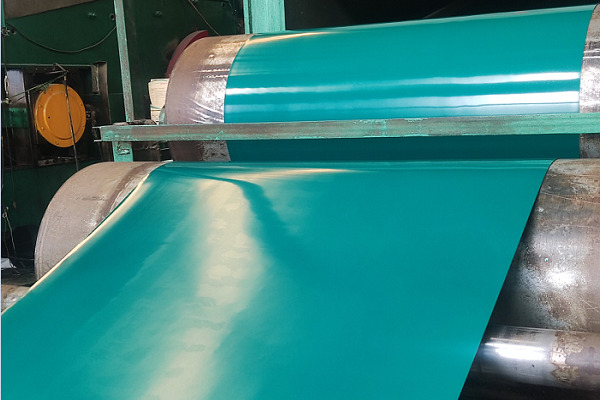

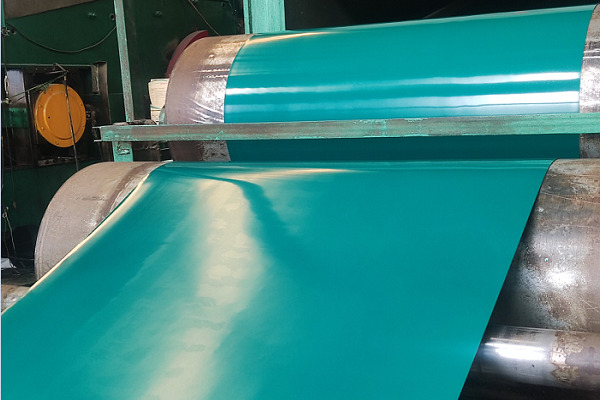

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.