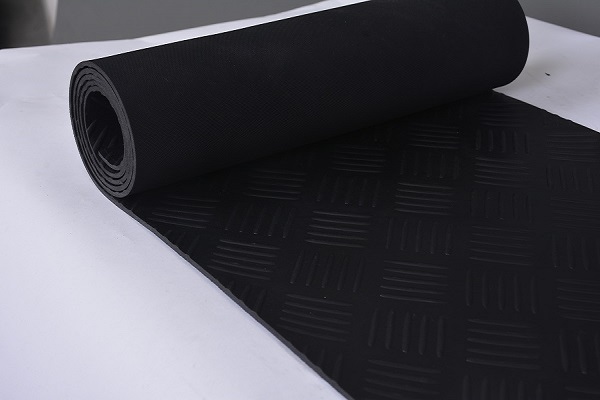

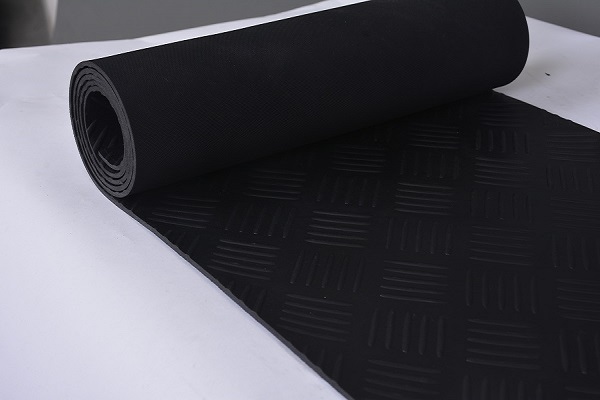

Anti-slip rubber sheets are widely used in various places. They not only effectively prevent slip accidents but also have good wear resistance and sound absorption properties.

However, with the passage of time and increased usage frequency, anti-slip rubber sheets may experience wear and aging. At this point, renovation is necessary to extend their service life and restore their good performance. The following are some tips and methods for renovating anti-slip rubber sheets.

Before starting the renovation of anti-slip rubber sheets, a comprehensive investigation of the existing floor conditions is an essential step. It is necessary to carefully inspect the flatness of the floor, damage conditions, and waterproof performance, etc. For example, if there are obvious unevenness on the floor, it may affect the subsequent laying effect of the rubber sheets; while severely damaged areas, such as cracks and damages, need to be repaired with priority. At the same time, the inspection of waterproof performance is also crucial, as any leakage problems on the floor may have a negative impact on the service life of the rubber sheets. Only by fully understanding the actual condition of the existing floor can the most suitable renovation plan be formulated.

>send emails to sales@jingdongrubber.com,get a quote now

The base treatment is an important step to ensure the tight adhesion of the rubber sheets to the floor.

Apply the base coating evenly on the floor, which can be done using a roller or brush. During the application process, it is necessary to maintain a certain thickness to provide sufficient adhesion for the subsequent laying of the rubber sheets. Usually, depending on the type of base coating and environmental conditions, it is necessary to wait for more than 24 hours for the base coating to dry completely. This step may seem simple, but it directly affects the quality and effect of the subsequent laying of the rubber sheets, so it must be taken seriously to ensure that the base coating is thoroughly dry and lay a solid foundation for the laying of the rubber sheets.

After the base coating is completely dry, the laying of the rubber sheets can be carried out. However, before laying, the rubber sheets need to be pre-treated.

First, trim the rubber sheets to the appropriate size to ensure a perfect fit for the area to be laid.

At the same time, carefully remove the dust and debris on the surface of the rubber sheets, as these impurities may affect the quality of the laying, resulting in gaps or loose adhesion between the rubber sheets and the floor.

Then, evenly apply the adhesive suitable for anti-slip rubber sheets on the back of the rubber sheets, and accurately lay the rubber sheets on the floor that has been pre-applied with adhesive.

During the laying process, apply appropriate pressure to ensure that the rubber sheets are fully adhered to the floor and air bubbles are eliminated. Only in this way can the rubber sheets be tightly connected to the floor and fully exert their anti-slip and wear-resistant properties.

After the laying of the rubber sheets is completed, it does not mean the end of the renovation work. Leak detection treatment is still necessary to ensure the waterproof performance of the floor. This step can effectively prevent water from seeping under the rubber sheets, avoiding problems such as damage or mold growth due to a humid environment. By carefully inspecting and treating possible leakage points, the overall quality and usage effect of the renovated anti-slip rubber sheets can be further improved.

The renovation of anti-slip rubber sheets is a work that requires rigorous operation and meticulous handling.

From the investigation of the existing floor conditions to the base treatment, rubber sheet laying, and leak detection treatment, each step is crucial. Only by strictly following the correct methods and procedures can the anti-slip rubber sheets regain their good performance, provide a safe and comfortable usage environment for people, and also extend their service life, achieving the rational utilization of resources and maximizing economic benefits.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.