In various industrial and technological fields,the application of silicone rubber sheets is becoming increasingly widespread.Whether it is for sealing in solar energy equipment or in the lamination process,the correctness of the installation method directly affects the performance and service life of the product.Mastering the correct installation steps of silicone rubber sheets not only ensures their full functionality but also effectively avoids problems caused by improper installation.

Preparations before installing silicone rubber sheets are crucial.

It is essential to ensure that the size of the silicone rubber sheet perfectly matches the installation position.Any deviation in size may lead to difficulties in subsequent installation or potential hazards during use.At the same time,the cleanliness of the silicone rubber sheet’s surface should not be overlooked.It must be kept clean and free of impurities to avoid affecting the bonding effect or introducing foreign contaminants.Additionally,depending on the specific application scenario,a series of necessary tools should be prepared,such as a scraper for applying the base adhesive,a spatula for flattening the silicone rubber sheet,and a cleaning cloth for the final cleaning.These preparations will lay a solid foundation for the subsequent installation steps.

Applying the base adhesive is a key step in the installation process of silicone rubber sheets.

Uniformly apply a layer of base adhesive on the designated installation surface.This step not only affects the bonding strength between the silicone rubber sheet and the installation surface but also influences the overall sealing and stability.The application of the base adhesive requires careful and even application to ensure that every area is properly treated,creating an ideal adhesion environment for the silicone rubber sheet.

>send emails to sales@jingdongrubber.com,get a quote now

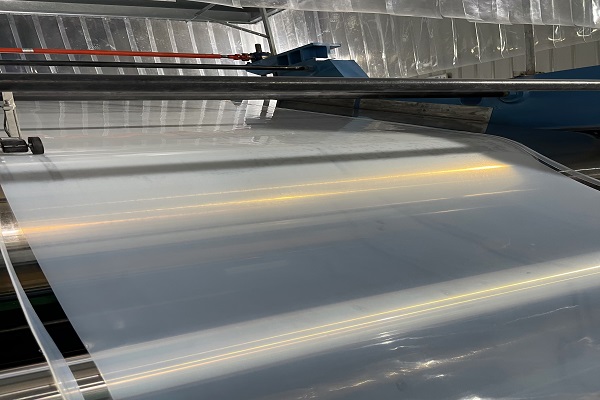

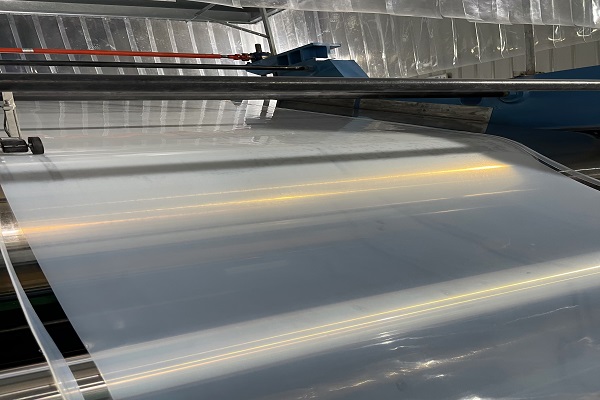

Next comes the actual laying of the silicone rubber sheet.

Place the prepared silicone rubber sheet accurately at the designated position.This step requires the operator to have a certain sense of space and fine operation skills.During the laying process,it is necessary to constantly pay attention to keeping the silicone rubber sheet flat to avoid wrinkles or air bubbles.These small problems may become major hazards in future use.Therefore,during the laying process,tools such as a spatula can be used for assistance to ensure that the silicone rubber sheet is closely attached to the installation surface without any gaps remaining.

It is particularly worth mentioning that in certain specific application scenarios,such as the lamination process,the installation of silicone rubber sheets also needs to consider its coefficient of thermal expansion.

Since the silicone rubber sheet expands when heated,a certain amount of space needs to be reserved during installation.It is generally recommended to maintain a 1-2mm gap between the silicone rubber sheet and the upper mold when heating on a laminator.In this way,after heating to 150 degrees Celsius for 2 hours,the silicone rubber sheet has enough space to expand thermally.Then,after closing the mold,it can ensure that the silicone rubber sheet remains flat and evenly stressed after cooling,without deformation or damage due to thermal expansion and contraction.

In addition to the above basic steps,there are also some details that deserve attention.

For example,during the application of the base adhesive and the laying of the silicone rubber sheet,excessive glue should be avoided to prevent waste or affect the bonding effect.At the same time,after installation,necessary inspections and tests should be carried out to ensure that the installation quality of the silicone rubber sheet meets the requirements and there are no omissions or defects.

The installation of silicone rubber sheets is a meticulous process that requires certain skills.

From preparations to applying the base adhesive,to the actual laying and subsequent processing,each step must be handled with care to ensure that the silicone rubber sheet can perform at its best,providing reliable support and protection for various industrial and technological applications.By following the correct installation method,we can not only extend the service life of the silicone rubber sheet but also enhance the stability and safety of the entire system.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.