Among various industrial materials, silicone rubber sheets have extensive applications in various fields due to their unique properties such as high temperature resistance and corrosion resistance. However, when exposed to specific environments, ozone resistance performance becomes a crucial indicator. So, how is the ozone resistance performance of silicone rubber sheets tested? And what standards do they follow?

Ozone, as a strong oxidant, has extremely strong corrosiveness and can react with many substances, accelerating the aging and damage of materials. For silicone rubber sheets, if they are exposed to an ozone-containing environment for a long time, their molecular structure may be damaged, leading to a decline in physical properties such as becoming brittle, cracking, and reduced strength, which seriously affects their service life and reliability. Therefore, testing the ozone resistance performance of silicone rubber sheets is particularly important, as it helps us understand the material’s performance in an ozone environment in advance, providing a strong basis for product design and application.

Currently, the ozone resistance performance testing of silicone rubber sheets is mainly carried out in accordance with relevant industry standards. These standards clearly stipulate each step of the testing process to ensure the accuracy and comparability of the test results.

In terms of testing methods, the common ones include static tensile test method and dynamic tensile test method.

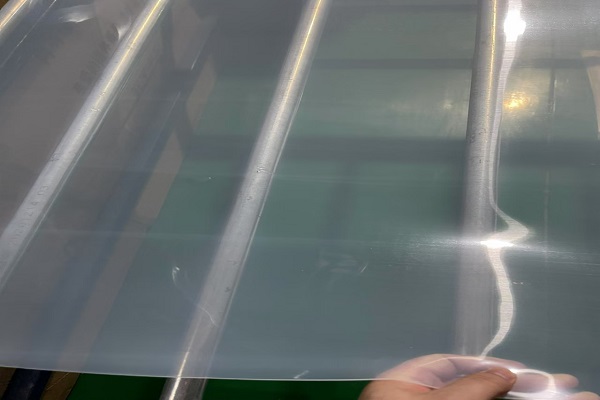

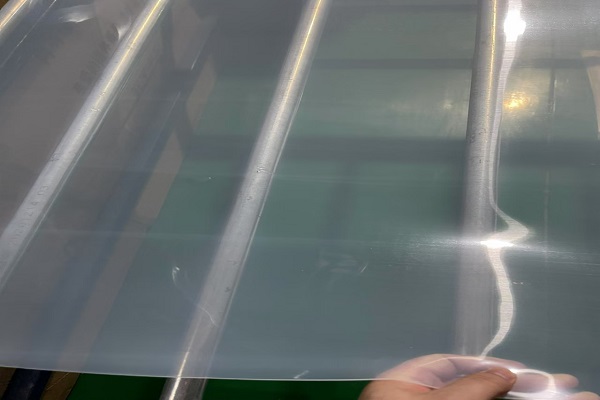

The static tensile test method involves fixing the silicone rubber sheet sample in a specific fixture to keep it in a certain tensile state, and then placing it in a closed test chamber filled with ozone. The purpose of tensile is to create stress concentration areas in the silicone rubber sheet, as ozone usually tends to cause cracks in these weak areas. The ozone concentration, temperature, and humidity in the test chamber are strictly controlled, for example, the ozone concentration is usually precisely set within a specific range, such as 50pphm, 100pphm, etc., the temperature may be controlled at around 40℃, and the humidity is also maintained at a relatively stable level, to simulate the actual usage or specific environmental conditions. Throughout the testing process, the changes on the surface of the sample are continuously observed, and the time when cracking occurs and the development of the cracks are recorded. After reaching the predetermined testing time, the sample is removed, and the ozone resistance performance grade of the silicone rubber sheet is evaluated based on the degree of cracking on its surface or other performance changes.

The dynamic tensile test method is based on the static tensile method, but the sample is subjected to periodic stretching and contracting movements in the tensile state, which is more in line with the dynamic force conditions of the silicone rubber sheet in actual use. This method is used to examine its ability to resist ozone erosion under dynamic conditions. The testing principle and control of environmental conditions are similar to the static tensile test, but it can more comprehensively reflect the ozone resistance performance of the material.

>send emails to sales@jingdongrubber.com,get a quote now

In terms of judgment criteria, the standards provide detailed descriptions of the surface changes corresponding to different grades of ozone resistance performance.

For example, grade one ozone resistance performance indicates that there are almost no obvious cracks or only extremely fine cracks on the surface of the sample under the specified testing time and ozone concentration; grade two allows for a small number of short cracks, but the crack length and distribution density are within a certain range; and so on. The lower the grade, the worse the ozone resistance performance. By comparing the tested sample with the descriptions and pictures in the standards, the ozone resistance performance grade of the silicone rubber sheet can be accurately determined.

In addition to the above conventional testing standards, in some special industry applications, more strict or targeted testing norms are formulated based on specific usage scenarios and requirements.

For instance, in the aerospace field, since silicone rubber sheets may be used in critical parts such as aircraft seals, the requirements for ozone resistance performance are extremely high. During testing, not only is the ozone concentration increased and the testing time prolonged, but more performance testing items are added, such as comparing the sealing performance before and after testing, to ensure that the silicone rubber sheet can maintain good performance in extreme ozone environments and guarantee flight safety.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.