Rubber mats,as common industrial and household items,do not have a fixed service life.Instead,it is influenced by multiple factors such as material quality,usage environment,frequency of use,and load.Different types of rubber mats show significant differences in lifespan due to their various application scenarios.

From the perspective of basic material,rubber mats made of high-quality shock-absorbing rubber often exhibit excellent durability-the service life of such products can typically exceed 10 years.

For instance,the rubber mats installed in new cars,if of decent quality,can maintain stable performance for 3 to 5 years under normal usage conditions;in contrast,those made of ordinary materials may need to be replaced after only 2 to 3 years.Taking the application in the automotive field as an example,the lifespan of engine mounts is closely related to the vehicle model and actual usage conditions:those prone to breakage may need to be replaced after about 50,000 kilometers of driving,while under normal usage conditions,they can last for more than 6 years;with proper maintenance,they can even retain their buffering performance when the car is replaced.The rear shock absorber top rubber in cars can last for 5 to 10 years under proper use and regular maintenance;the replacement cycle for the front shock absorber top rubber is generally around 40,000 kilometers;and the buffer rubber is generally recommended to be inspected or replaced every 3 years or after 60,000 kilometers of driving.

Environmental factors also significantly affect the lifespan of rubber mats.

Long-term exposure to damp and high-temperature environments,or frequent driving on rough roads,can accelerate the aging of rubber materials.For example,in high-temperature conditions,the molecular structure of rubber is prone to change,leading to a decrease in elasticity;in damp environments,corrosion problems may occur,all of which can cause wear,deformation,and thus shorten the service life.Conversely,maintaining a dry and stable usage environment can effectively delay the aging process.Laboratory data shows that the same batch of rubber sound insulation pads can last for over 10 years with good performance in a dry and suitable indoor environment,but only 2 to 3 years in high-temperature and high-humidity outdoor conditions.

The frequency of use and load size are also key variables determining the lifespan of rubber mats.

Frequent and high-intensity use can accelerate material fatigue damage,especially when subjected to loads exceeding the design capacity,microscopic cracks will inevitably occur.For example,the lifespan of motorcycle buffer rubber ranges from several thousand kilometers to tens of thousands of kilometers,and this difference mainly stems from the load variations caused by different riding habits.In industrial scenarios where heavy loads need to be carried for long periods,regular inspection of the integrity of the load-bearing parts is particularly important.

Special types of rubber products exhibit more excellent durability.

Polyurethane rubber sound insulation pads,made by mixing rubber particles with PU foam,not only have excellent sound insulation capabilities but also offer advantages such as water resistance,moisture resistance,non-toxicity,and environmental friendliness,with a lifespan of up to 50 years or more.Ethylene propylene diene monomer(EPDM)rubber mats stand out particularly:they can serve stably for 15 to 25 years in normal indoor environments;even in harsh outdoor conditions,they can maintain a stable period of 10 to 15 years;and in household use or when installed according to specifications,their lifespan can reach 50 years or more,even exceeding 70 or 100 years.However,under extreme working conditions,their lifespan may be reduced to 5 to 8 years,which reminds us to fully consider the specific application scenarios when selecting products.

Regular maintenance and care play a crucial role in extending the lifespan of rubber mats.

Regular cleaning of surface dust and impurities can reduce frictional wear,avoiding long-term pressure from heavy objects helps prevent deformation,and timely replacement of the bottom anti-slip pads can maintain structural stability.For insulating rubber products,it is also necessary to avoid environments that accelerate aging,such as high temperatures and oil stains.Through scientific usage management and appropriate maintenance measures,rubber mats can fully demonstrate their maximum value in practical applications.

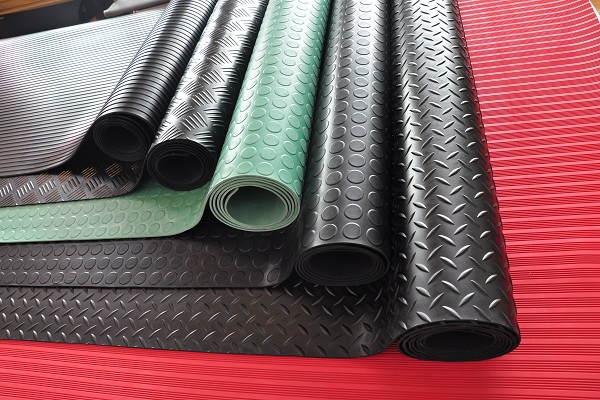

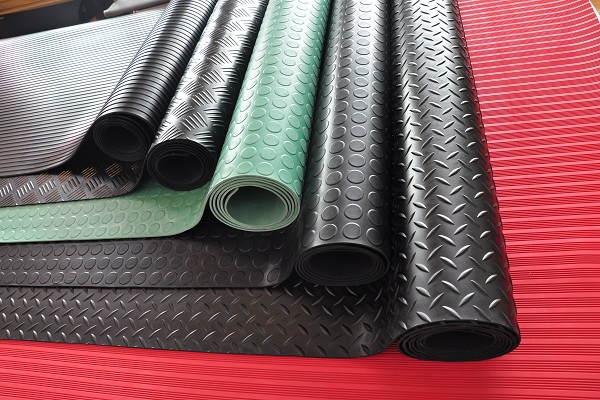

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.