Anti-static rubber sheets play a crucial role in modern industry and daily life,effectively preventing the adverse effects of static electricity and safeguarding the safety of electronic equipment.The following will detail the installation steps of anti-static rubber sheets.

Preparations

Before laying the anti-static rubber sheets,thorough preparations are essential.Firstly,gather all the necessary tools and materials,such as rulers,knives,glue or double-sided tape,silicone sealant,and masking tape,etc.The availability of these tools and materials will ensure a smooth installation process.Additionally,choose an appropriate jointing method based on actual needs.Common methods include direct laying,overlapping,or cross-laying.Due to the high adhesion between anti-static rubber sheets,direct laying is the most commonly used option.

Ground Preparation

Understanding the ground conditions is a crucial prerequisite for installation.The ground should be a smooth surface such as cement,terrazzo,tiles,or wood,free of unevenness,with no significant depressions,sufficient strength,no sanding or peeling,and kept dry.Afterward,clean the ground thoroughly with cleaning solution and detergent to ensure it is free of dust and debris,allowing for optimal contact between the glue or double-sided tape and the ground for the best bonding effect.

>send emails to sales@jingdongrubber.com,get a quote now

Laying the Conductive Grid

When laying,a copper conductive grid should be set up on a flat ground.The grid should be 0.02mm thick and 20mm wide,fixed with conductive adhesive,with grounding clips spaced 2-3 meters apart.Specifically,use copper strips that are 0.25mm thick and 2.5cm wide(the number of copper strips can be determined based on the width of the ground,generally one is used every two to three meters),and connect the other end of the laid copper strips to the external grounding electrode.

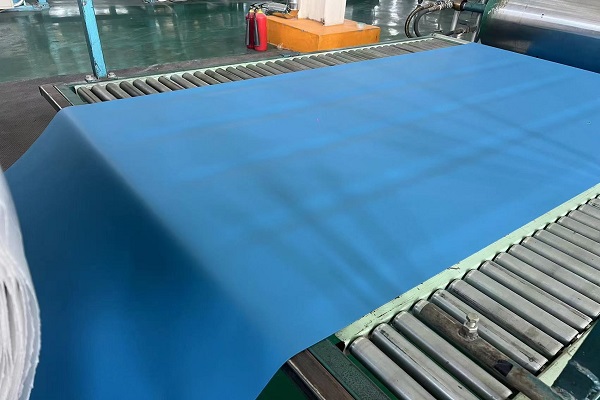

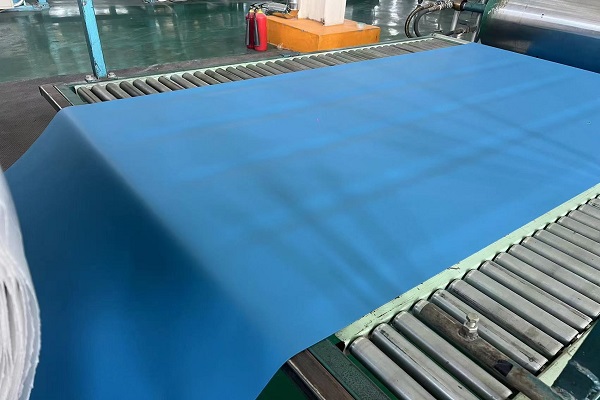

Laying the Rubber Sheets

After the conductive grid is laid,the anti-static rubber sheets can be laid on the ground one by one.If the gaps at the bottom are large,use a knife to cut them to make the gaps as small as possible.During the laying process,lay the rubber sheets flat on the ground and gently press them to ensure a tight fit with the ground.If using glue,apply it evenly at the joints and roll it several times with a heavy roller to make the surface smooth and straight.After 48 hours at room temperature,the glue will fully cure,and the rubber sheets will achieve the best fixation effect,at which point they can be used normally.However,there is also a view that they can be used normally after 2 days at room temperature.

Post-installation Inspection and Maintenance

After installation,a comprehensive inspection of the anti-static rubber sheets should be conducted.Check if the surface of the rubber sheets is flat,free of bubbles or wrinkles.If any issues are found,they should be addressed promptly to ensure the performance and service life of the anti-static rubber sheets.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.