Nitrile rubber sheet,a synthetic rubber,has widespread applications in industry due to its excellent oil resistance and wear resistance.This material is not only used to manufacture automotive oil seals,fuel tanks,and rubber hoses,but also widely used in the fields of aerospace and petrochemical.

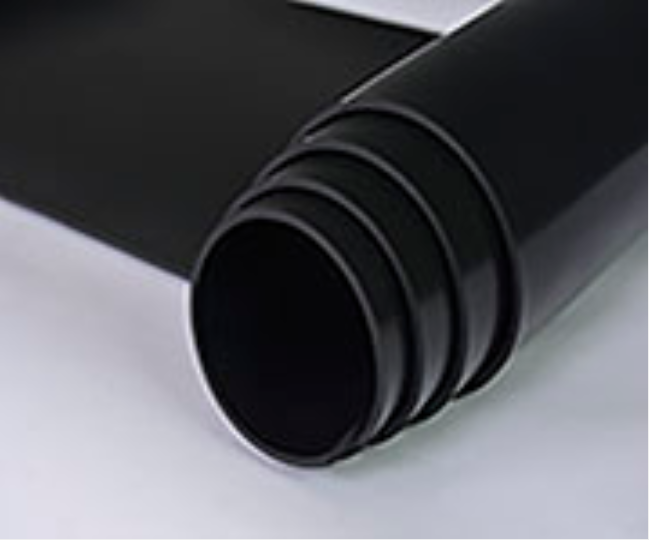

Nitrile rubber sheet is a high molecular material made by copolymerizing butadiene and acrylonitrile.It has excellent oil resistance and wear resistance,and can withstand high temperature and high pressure working conditions,so it has wide applications in many fields.

Let’s take a look at the physical and chemical properties of nitrile rubber sheet.

Nitrile rubber sheet has good elasticity and toughness,and can maintain its shape under stretching or compression.At the same time,it also has good weather resistance and aging resistance,and can maintain stable performance for a long time.In addition,due to the presence of polar functional groups in its molecular structure,nitrile rubber sheet has good oil resistance and wear resistance.These excellent properties have made nitrile rubber sheet widely used in various fields.

Let’s take a look at the application areas of nitrile rubber sheet.

Due to its excellent oil resistance and wear resistance,nitrile rubber sheet is widely used in the automotive manufacturing industry.For example,it can be used to manufacture car oil seals,fuel tanks,and rubber hoses,etc.,to ensure the stability and safety of the car during operation.

In addition,neoprene rubber sheets are widely used in the fields of aerospace and petrochemicals.In the aerospace field,neoprene rubber sheets can be used to manufacture seals and fuel tanks for aircraft;while in the petrochemical field,it can be used to manufacture various corrosion-resistant pipes and containers.