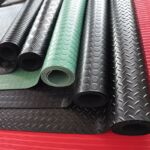

What is the rebound rate of natural rubber sheets

The rebound rate of natural rubber sheets is an important physical indicator, which is related to the performance and quality of rubber products. So, what exactly is the rebound rate of natural rubber sheets? We need to understand what the rebound rate is. Simply put, the rebound rate refers to the ability of a material to return to its…