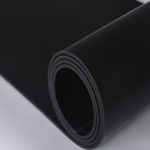

What is the lowest temperature that nitrile rubber sheet can withstand

Nitrile rubber sheet,as a widely used sealing and damping material in industrial fields,has always been the focus of engineers and technicians for its performance characteristics.Among the many performance indicators,low-temperature resistance is particularly important because it directly relates to the material’s suitability and service life in specific environments.What is the lowest temperature that nitrile rubber sheet can withstand?Today,Jingdong Rubber,a rubber…