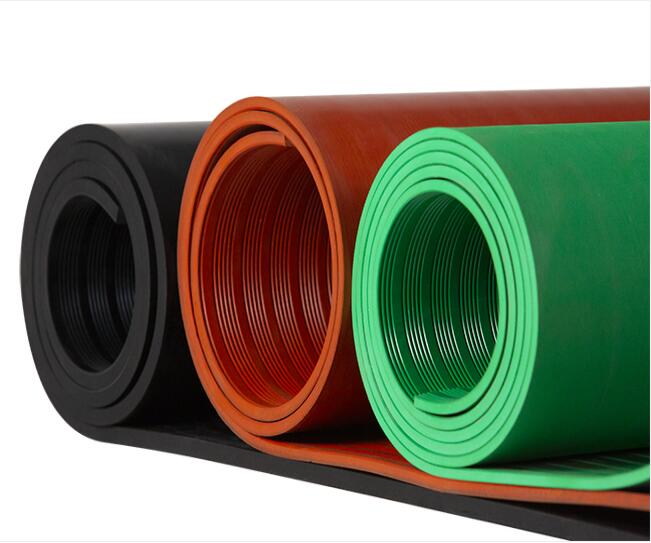

Rubber sheet,a common yet vital industrial material,is widely used in various fields.In particular,it plays an indispensable role in places where non slip and wear-resistant properties are required,such as railway crossings and factory workshops.However,how to properly install rubber sheet to ensure its stability,durability,and maximum effectiveness?

The choice of fixing method is like choosing how to fasten a safety belt,which needs to consider both comfort and safety.Considering the relative position of the rubber sheet with the track and the height of the surrounding ground,expansion bolts or rubber adhesive fixing methods have been developed.This is like hanging a picture on the wall,ensuring that the frame is level and that the nails are firmly driven into the wall to prevent the frame from falling.

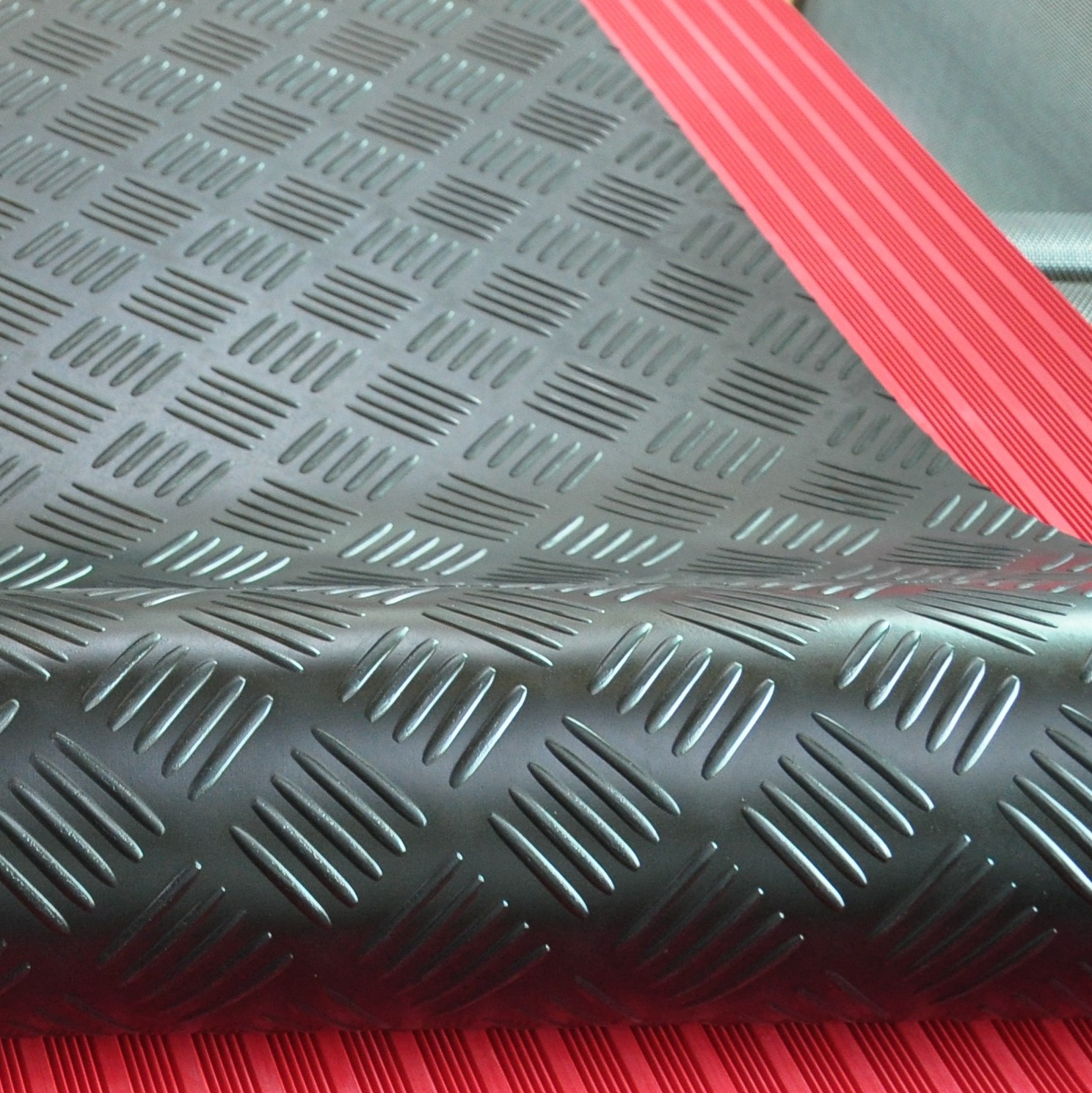

The laying method is the key step in turning the preparation work results into actual effectiveness.Before laying,the foundation of the crossing needs to be cleaned,just like tidying up the floor of the room to ensure that there are no sand particles or dust that may affect the laying effect.The rubber sheet should be laid flat,with a height difference of no more than 3mm with the track,just like the transition between the floor and the threshold,which not only ensures beauty but also prevents people from tripping.The edges should be evenly treated to ensure the quality of the crossing appearance.

Details determine success or failure,and the size control of rubber sheet is no exception.Just like custom-made clothes,the length,width,and gap design must be precise.The length is usually 2-3 meters,the width is about 1.5 meters,with appropriate gaps to accommodate seasonal expansion and contraction,like the expansion joints on bridges,which are not only a matter of aesthetics but also a wise move to combat natural changes.