Rubber sheet,a material that we see everywhere in our daily lives,brings great convenience to our lives.But do you know how to make rubber sheet?

In fact,its production process is not complicated.It only needs to go through the steps of raw material preparation,mixing,compounding,vulcanization,trimming the edges,inspection,and packaging to complete.

The raw material of rubber sheet is mainly raw rubber,a natural substance extracted from rubber trees.At the same time,some auxiliary materials such as auxiliaries are also needed,which can improve certain properties of rubber.

Then,the basic materials are kneaded to make them mix with the auxiliaries more fully.This process requires professional equipment and technology to ensure uniform mixing of the materials.

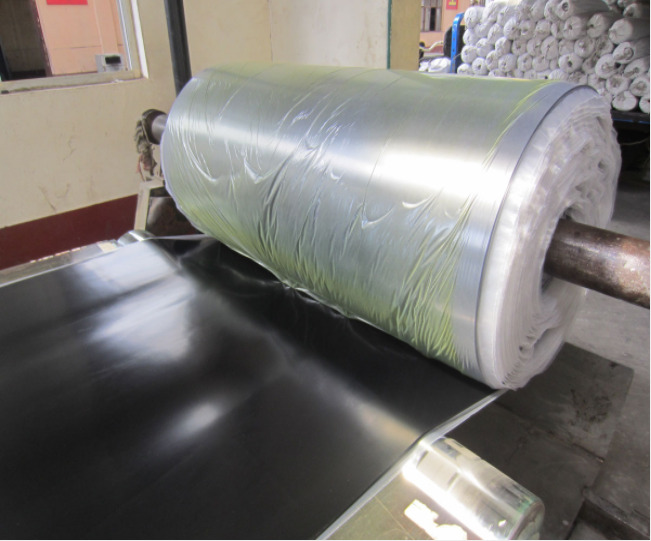

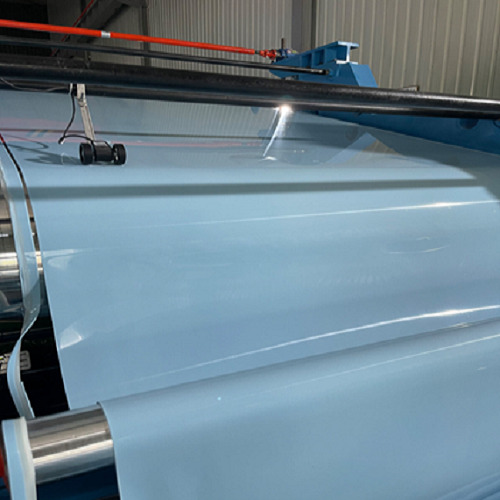

Next,the kneaded raw rubber and auxiliary materials are mixed mechanically to evenly disperse the auxiliaries in the rubber,forming a compounded rubber.During this process,the temperature and time need to be controlled to ensure the quality of the compounded rubber.After compounding,the compounded rubber is cut into the appropriate raw materials according to the size of the desired product and waiting for vulcanization.

Vulcanization is an important step in the production process of rubber.It is the process of melting the raw materials at high temperature and solidifying them into shape in the mold.

The solidified materials need to be trimmed and the edges are trimmed by hand and then mechanically polished.This step is to improve the appearance and accuracy of the product.

Next,comes the inspection stage.Each rubber sheet needs to go through strict quality inspection to ensure that its parameters meet the standards.

Finally,the qualified rubber sheets will be packaged and shipped.

The production of rubber sheets is a simple yet complex process that requires specialized technology and equipment.However,as long as we have the right production method,we can manufacture high-quality rubber sheets to bring more convenience to our lives.