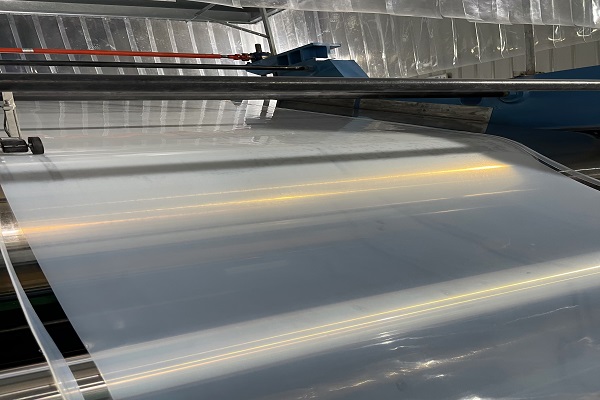

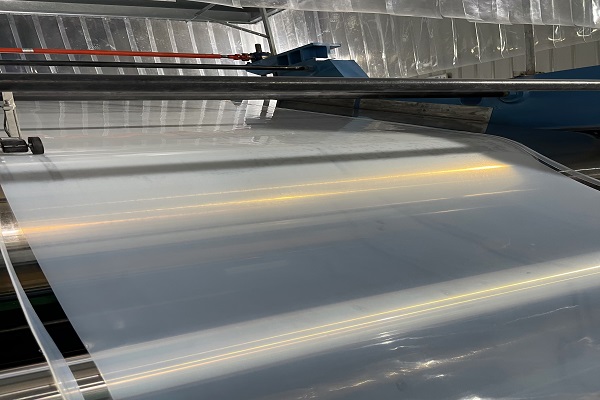

In various industrial and technological fields,the application of silicone rubber sheets is becoming increasingly widespread.Whether it is for sealing in solar energy equipment or in the lamination process,安装方法的正确性直接影响产品的性能和服务寿命。对有机硅橡胶板的正确安装步骤不仅确保其完整功能,而且还有效地避免了安装不当引起的问题.

安装硅胶橡胶板之前的准备工作至关重要.

It is essential to ensure that the size of the silicone rubber sheet perfectly matches the installation position.Any deviation in size may lead to difficulties in subsequent installation or potential hazards during use.At the same time,the cleanliness of the silicone rubber sheet’s surface should not be overlooked.It must be kept clean and free of impurities to avoid affecting the bonding effect or introducing foreign contaminants.Additionally,depending on the specific application scenario,a series of necessary tools should be prepared,such as a scraper for applying the base adhesive,a spatula for flattening the silicone rubber sheet,and a cleaning cloth for the final cleaning.These preparations will lay a solid foundation for the subsequent installation steps.

Applying the base adhesive is a key step in the installation process of silicone rubber sheets.

Uniformly apply a layer of base adhesive on the designated installation surface.This step not only affects the bonding strength between the silicone rubber sheet and the installation surface but also influences the overall sealing and stability.The application of the base adhesive requires careful and even application to ensure that every area is properly treated,creating an ideal adhesion environment for the silicone rubber sheet.

>将电子邮件发送到sales@jingdongrubber.com,立即获取报价

Next comes the actual laying of the silicone rubber sheet.

将准备好的硅胶橡皮纸精确地放在指定位置。此步骤要求操作员具有一定的空间和精细的操作技巧。,有必要不断注意保持有机硅橡胶板平整以避免皱纹或气泡。这些小问题可能会在以后的使用中成为主要危害。因此,在铺设过程中,诸如刮铲之类的工具可用于帮助,以确保硅胶橡皮纸紧密连接到安装表面,而无需剩下任何间隙.

特别值得一提的是,在某些特定的应用程序方案中,例如层压过程,硅胶橡胶板的安装还需要考虑其热膨胀系数.

自从 硅橡胶板 加热时膨胀,在安装过程中需要保留一定数量的空间。通常建议在层压板上加热时保持有机硅橡皮纸和上部模具之间的1-2mm差距。,加热后 150 摄氏摄氏度 2 小时,硅胶橡胶板有足够的空间来热膨胀。,关闭模具后,它可以确保硅胶橡胶板在冷却后保持平坦,压力均匀,由于热膨胀和收缩而没有变形或损坏.

除了上述基本步骤,还有一些值得关注的细节.

例如,在应用碱粘合剂和硅橡胶板的铺设过程中,应避免过多的胶水以防止浪费或影响粘合效应。,安装后,应进行必要的检查和测试,以确保有机硅橡皮纸的安装质量满足要求,并且没有遗漏或缺陷.

硅胶橡胶板的安装是一个细致的过程,需要某些技能.

从准备工作到涂抹碱基粘合剂,进行实际的铺设和后续处理,每个步骤都必须谨慎处理,以确保有机硅橡胶板可以表现最好,为各种工业和技术应用提供可靠的支持和保护。遵循正确的安装方法,我们不仅可以延长硅橡胶板的使用寿命,还可以提高整个系统的稳定性和安全性.

Jingdong Rubber Co., 有限公司. 是一家专业的橡胶板生产厂家, 生产硅橡胶板, 天然橡胶板, 氟橡胶板, 氯丁橡胶板, 绝缘橡胶板,三元乙丙橡胶板, 耐油橡胶板, 防静电橡胶板, 阻燃橡胶板, 导电橡胶板, 防滑橡胶板, 和牛棚垫, ETC. 和 40 多年行业经验, 畅销国内外. 如果您需要我们的任何产品,请发送电子邮件至 sales@jingdongrubber.com.