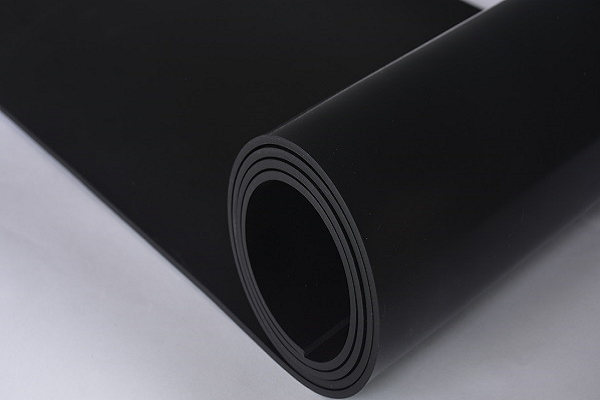

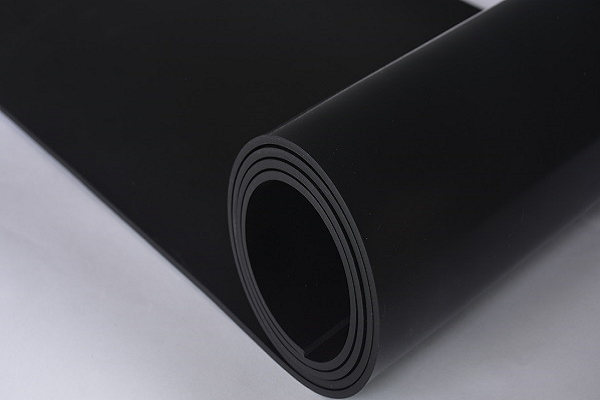

Neoprene rubber sheets,as a high-performance synthetic material,have demonstrated their unique value in numerous fields.They not only possess excellent physical and mechanical properties but also excel in oil resistance,heat resistance,flame retardancy,and other aspects,thus becoming an indispensable part of industrial and consumer products.

The main component of neoprene rubber sheets is chloroprene,a synthetic rubber produced throughα-polymerization.Neoprene rubber was first developed in the 1930s and quickly became the first synthetic rubber to be mass-produced.The unique properties of this material are mainly attributed to its molecular structure,with the presence of chlorine atoms endowing it with characteristics that other rubbers lack.

In terms of physical properties,neoprene rubber sheets perform exceptionally well.They have high tensile strength and excellent physical toughness,enabling them to maintain good elasticity even under high stress and strain.Additionally,neoprene rubber sheets have good heat resistance and can withstand high-temperature environments without significant deformation or damage.This feature makes them widely used in applications requiring high-temperature resistance,such as rocket fuel pipelines and industrial seals.

>send emails to sales@jingdongrubber.com,get a quote now

Another significant advantage of neoprene rubber sheets is their outstanding resistance to chemical corrosion.They have good resistance to oils,acids,bases,and various chemical reagents,making them widely used as sealing materials in the chemical and petroleum industries.For example,in general valves,chloroprene rubber is often used as a soft seal surface,suitable for various media,including animal oils,vegetable oils,inorganic lubricating oils,and highly corrosive mud with a wide range of pH values.

Neoprene rubber sheets also have good weather resistance,meaning they can maintain their performance even after long-term outdoor exposure.Although their weather resistance is slightly inferior to that of EPDM rubber sheets,they still outperform many other types of rubber.This characteristic makes neoprene rubber sheets valuable in the manufacture of weather-resistant products and outdoor building materials.

Despite their many advantages,neoprene rubber sheets also have some drawbacks.The most significant disadvantage is their poor cold resistance and storage stability.In low-temperature environments,neoprene rubber sheets may become brittle,affecting their service life and performance.Additionally,if not properly controlled during production and use,such as with excessively high polymerization temperatures,final conversion rates,or exposure to air(oxygen),the product quality can decline.

The production process of neoprene rubber sheets is relatively complex.It is typically produced using emulsion polymerization,mostly in a single-batch reactor.During this process,the polymerization temperature is usually controlled at 40-60°C,and the conversion rate is around 90%.To ensure product quality,the molecular weight is regulated using a sulfur-thiourea system.

Neoprene rubber sheets are versatile elastomers with superior comprehensive performance,widely used in industries such as manufacturing,construction,automotive,and home furnishings.Whether as a general-purpose rubber or a specialty rubber,they play an irreplaceable role in modern production and daily life.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.