在各种工业材料中, 硅胶橡胶板在各个领域都有广泛的应用,因为它们的独特特性(例如高温耐性和耐腐蚀性). 然而, 当暴露于特定环境时, 臭氧抵抗性能成为关键指标. 所以, 如何测试有机硅橡胶板的臭氧耐药性能? 他们遵循什么标准?

臭氧, 作为强氧化剂, 具有极强的腐蚀性,可以与许多物质做出反应, 加速材料的老化和损坏. 用于硅胶橡胶板, 如果他们长时间暴露于含臭氧的环境, 它们的分子结构可能会损坏, 导致物理特性下降,例如变脆, 破裂, 并降低强度, 严重影响他们的使用寿命和可靠性. 所以, 测试有机硅橡胶板的臭氧阻力性能尤为重要, 因为它有助于我们事先了解材料在臭氧环境中的性能, 为产品设计和应用提供强大的基础.

现在, 有机硅橡胶板的臭氧抵抗性能测试主要按照相关的行业标准进行. 这些标准清楚地规定了测试过程的每个步骤,以确保测试结果的准确性和可比性.

在测试方法方面, 常见的包括静态拉伸测试方法和动态拉伸测试方法.

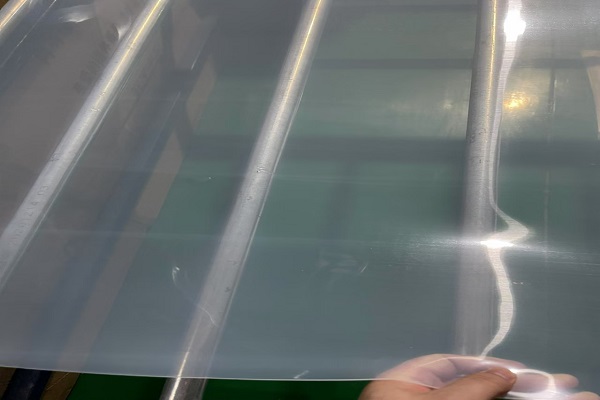

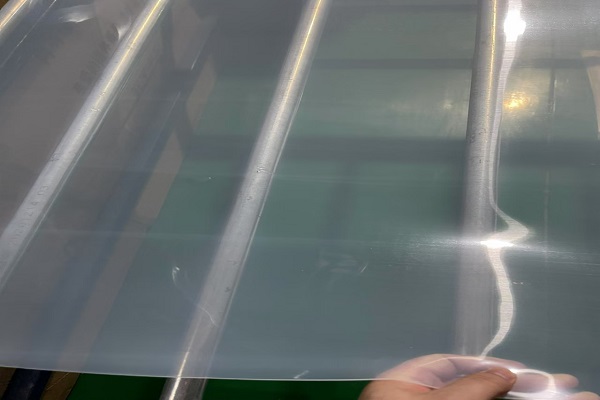

静态拉伸测试方法涉及将硅酮橡皮纸样品固定在特定的固定装置中,以使其保持一定的拉伸状态, 然后将其放在装满臭氧的封闭测试室中. 拉伸的目的是在硅胶板上创建应力浓度区域, 因为臭氧通常倾向于在这些薄弱区域引起裂缝. 臭氧浓度, 温度, 测试室中的湿度受到严格控制, 例如, 臭氧浓度通常精确设置在特定范围内, 例如50pphm, 100PPHM, ETC。, 温度可以在40℃左右控制, 而且湿度也保持在相对稳定的水平, 模拟实际使用或特定的环境条件. 在整个测试过程中, 连续观察样品表面的变化, 以及发生裂缝的时间和裂缝的发展. 达到预定的测试时间后, 取出样品, 并根据其表面上的破裂程度或其他性能变化评估了硅树脂橡胶板的臭氧抗性性能等级.

动态拉伸测试方法基于静态拉伸方法, 但是样本在拉伸状态下经过周期性拉伸和收缩运动, 这更符合实际使用中有机硅橡胶板的动态力条件. 该方法用于检查其在动态条件下抵抗臭氧侵蚀的能力. 环境条件的测试原理和控制与静态拉伸测试相似, 但是它可以更全面地反映材料的臭氧抵抗性能.

>将电子邮件发送到sales@jingdongrubber.com,立即获取报价

根据判断标准, 标准提供了对应于不同等级臭氧耐药性能的表面变化的详细描述.

例如, 一年级的臭氧抗性性能表明,在指定的测试时间和臭氧浓度下,样品表面上几乎没有明显的裂缝或极为细的裂纹; 二级允许少量短裂缝, 但是裂纹长度和分布密度在一定范围内; 等等. 等级越低, 臭氧抵抗性能越差. 通过将测试样本与标准中的描述和图片进行比较, 可以准确确定有机硅橡胶板的臭氧电阻性能等级.

除了上述常规测试标准, 在某些特殊行业应用中, 根据特定的用法方案和要求制定了更严格或有针对性的测试规范.

例如, 在航空航天领域, 由于硅胶橡胶板可用于关键部件,例如飞机密封, 臭氧阻力性能的要求非常高. 在测试期间, 不仅臭氧浓度增加,测试时间延长, 但是添加了更多的性能测试项目, 例如比较测试前后的密封性能, 为了确保有机硅橡胶板可以在极端臭氧环境中保持良好的性能并确保飞行安全.

Jingdong Rubber Co., 有限公司. 是一家专业的橡胶板生产厂家, 生产 硅橡胶板, 天然橡胶板, 氟橡胶板, 氯丁橡胶板, 绝缘橡胶板,三元乙丙橡胶板, 耐油橡胶板, 防静电橡胶板, 阻燃橡胶板, 导电橡胶板, 防滑橡胶板, 和牛棚垫, ETC. 和 40 多年行业经验, 畅销国内外. 如果您需要我们的任何产品,请发送电子邮件至 sales@jingdongrubber.com.