In industrial settings such as warehouses and workshops,safety and anti slip measures are of paramount importance.Anti slip rubber sheets,as an effective ground protection material,play a crucial role in ensuring both performance and safety.The selection of their size standards directly affects their application effectiveness in various scenarios.

Common size specifications include 3mm x 1m x 10m,3mm x 1.2m x 10m,3mm x 1.5m x 10m,5mm x 1m x 10m,5mm x 1.2m x 10m,and 5mm x 1.5m x 10m.These specifications mainly cover widths ranging from 1 meter to 1.5 meters,a length of 10 meters,and thicknesses of 3mm and 5mm.This diverse range of sizes can meet the needs of different places,whether it’s a small warehouse or a large workshop,ensuring there is a suitable rubber sheet for every application.

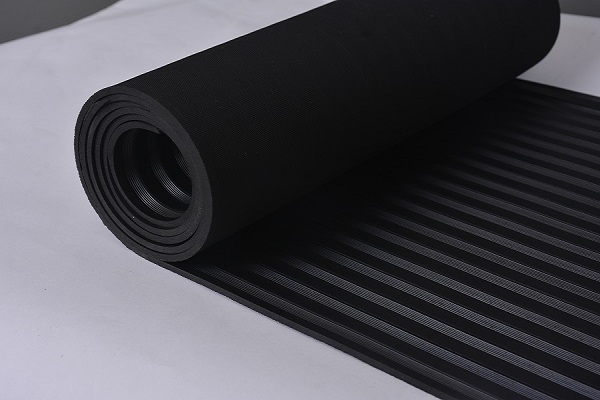

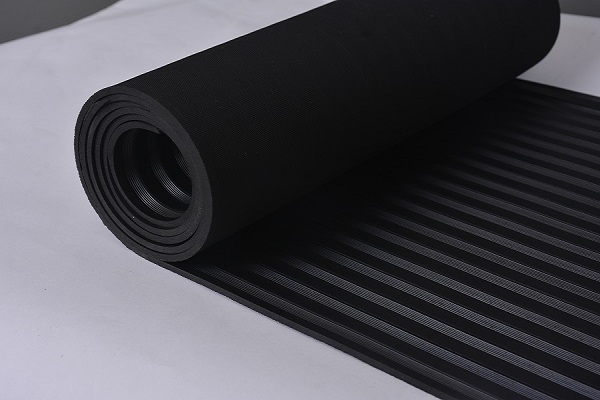

Apart from size,the material and surface texture of anti slip rubber sheets are also important factors affecting their anti slip performance.Generally,high-quality anti slip rubber sheets are made of superior rubber materials,offering good elasticity and wear resistance,effectively preventing workers from slipping during operations.In terms of surface texture,multi-textured designs such as willow leaf patterns,dot patterns,and stripes not only increase friction but also enhance drainage performance,further improving the anti slip effect.

>send emails to sales@jingdongrubber.com,get a quote now

When choosing anti slip rubber sheets,it is also necessary to make reasonable combinations based on the actual application scenarios.For example,for workshop floors that frequently have forklifts or other heavy machinery passing through,it is recommended to choose thicker rubber sheets,such as 5mm thick ones,to enhance their load-bearing and shock-absorbing capabilities.For areas with high foot traffic but no heavy loads,such as warehouse aisles or employee rest areas,3mm thick rubber sheets are sufficient.

When installing anti slip rubber sheets,some details should also be noted.Firstly,ensure the ground is flat and clean,free of oil and debris,to avoid affecting the adhesion of the rubber sheets.Secondly,during the laying process,pay attention to the tight connection between the rubber sheets to avoid gaps or overlaps.Finally,when cutting the rubber sheets according to actual needs,use professional tools to ensure neat and smooth cuts.

Anti slip measures in industrial settings such as warehouses and workshops cannot be ignored.Choosing the right anti slip rubber sheets and installing them correctly are key steps in ensuring safety.By understanding the characteristics and application ranges of different size specifications and making reasonable choices based on actual needs,the effectiveness of anti slip rubber sheets can be maximized,providing a safe and comfortable working environment for staff.At the same time,correct installation and maintenance can also extend the service life of the rubber sheets and reduce the long-term operating costs of enterprises.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.