Natural rubber sheet, as an important industrial material, is widely used in various fields. What is the production process of natural rubber sheet? Let’s have a brief introduction from Jingdong Rubber.

The pretreatment of raw materials is crucial in the production of natural rubber sheet.

The auxiliaries need to be dried to avoid clumping and uneven dispersion during mixing, which will affect product quality.

In addition, the rubber needs to be plasticized to improve its plasticity for subsequent processing.

The plasticizing methods include mechanical plasticization and thermal plasticization.

The next step is the mixing process, in which the plasticized rubber and auxiliaries are mixed together through mechanical mixing to evenly disperse the auxiliaries in the rubber.

The compounded rubber is the semi-finished product material for manufacturing rubber products, and its quality directly affects the performance of the final product.

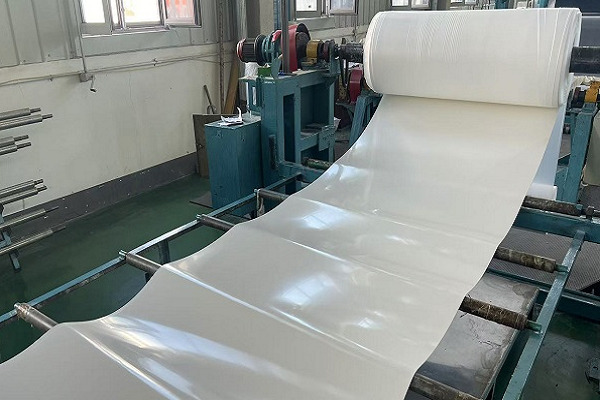

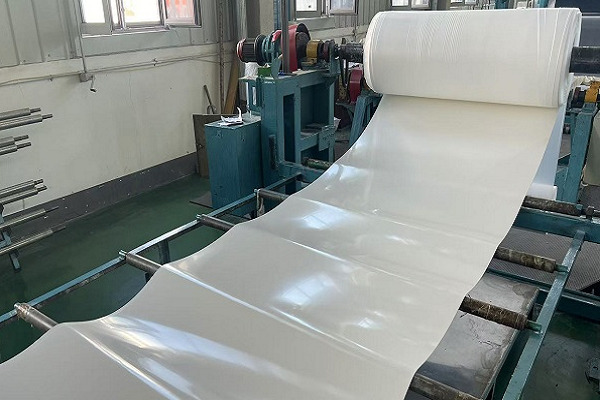

The shaping process is also a key step in the production of natural rubber sheet.

According to the shape and size requirements of the product, various shaping methods such as calendering, extrusion, and molding can be selected.

Different shaping methods are suitable for different types of rubber products. Simple sheet and plate products are usually calendered, while complex rubber products require extrusion or molding.

Sulfurization is the most important process in the rubber processing process.

By adding sulfuring agents and heating and holding at a specified temperature, the linear molecules of the rubber are formed into a three-dimensional network structure, thereby improving the elasticity of the rubber.

The types of sulfuring agents are numerous, including sulfur, organic polysulfides, peroxides, and metal oxides.

The control of sulfurization degree is crucial for the performance of rubber products. Under-sulfuration and over-sulfuration will both lead to a decline in rubber performance.

For example, increasing strength can be achieved by adding hard carbon black or blending with phenolic resin; increasing wear resistance can be achieved by selecting hard carbon black; for products with high gas tightness requirements, the use of components with high volatility should be reduced; and increasing heat resistance can be achieved by using new vulcanization processes.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, Neoprene Rubber Sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with nearly 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.