天然橡胶板, 作为重要的工业材料, 广泛应用于各个领域. 天然橡胶板的生产工艺是怎样的? Let’s have a brief introduction from Jingdong Rubber.

The pretreatment of raw materials is crucial in the production of natural rubber sheet.

The auxiliaries need to be dried to avoid clumping and uneven dispersion during mixing, which will affect product quality.

此外, the rubber needs to be plasticized to improve its plasticity for subsequent processing.

The plasticizing methods include mechanical plasticization and thermal plasticization.

The next step is the mixing process, in which the plasticized rubber and auxiliaries are mixed together through mechanical mixing to evenly disperse the auxiliaries in the rubber.

The compounded rubber is the semi-finished product material for manufacturing rubber products, and its quality directly affects the performance of the final product.

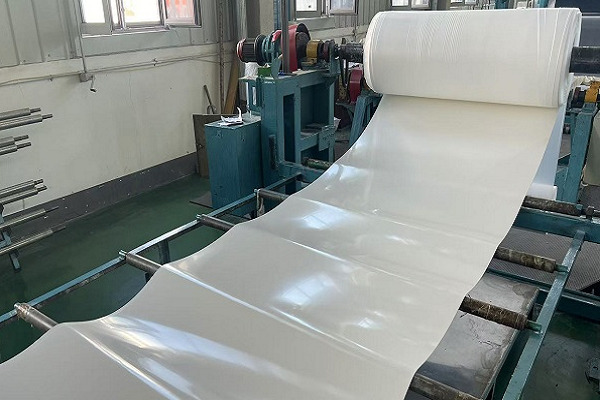

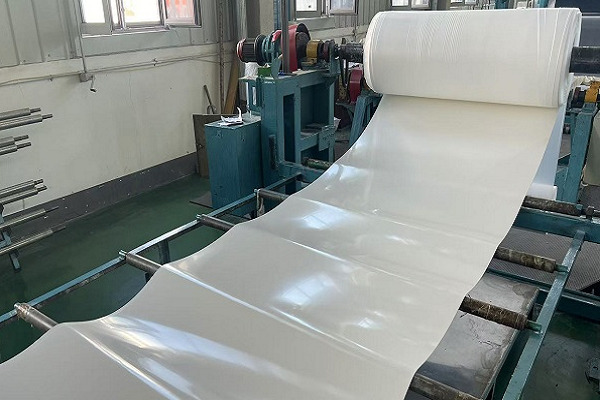

The shaping process is also a key step in the production of natural rubber sheet.

According to the shape and size requirements of the product, various shaping methods such as calendering, 挤压, and molding can be selected.

Different shaping methods are suitable for different types of rubber products. Simple sheet and plate products are usually calendered, while complex rubber products require extrusion or molding.

Sulfurization is the most important process in the rubber processing process.

By adding sulfuring agents and heating and holding at a specified temperature, the linear molecules of the rubber are formed into a three-dimensional network structure, thereby improving the elasticity of the rubber.

硫化剂的种类很多, 包括硫磺, 有机多硫化物, 过氧化物, 和金属氧化物.

硫化度的控制对于橡胶制品的性能至关重要. 硫化不足和硫化过多都会导致橡胶性能下降.

例如, 通过添加硬质炭黑或与酚醛树脂共混可以提高强度; 通过选择硬质炭黑可以提高耐磨性; 适用于气密性要求高的产品, 应减少高挥发性成分的使用; 通过使用新的硫化工艺可以提高耐热性.

Jingdong Rubber Co., 有限公司. 是一家专业的橡胶板生产厂家, 生产 硅橡胶板, 天然橡胶板, 氟橡胶板, 氯丁橡胶板, 绝缘橡胶板,三元乙丙橡胶板, 耐油橡胶板, 防静电橡胶板, 阻燃橡胶板, 导电橡胶板, 防滑橡胶板, 和牛棚垫, ETC. 与几乎 40 多年行业经验, 畅销国内外. 如果您需要我们的任何产品,请发送电子邮件至 sales@jingdongrubber.com.