In modern industrial production,sealing technology for chemical equipment is a crucial link to ensure safety,efficiency,and environmental protection.Particularly,industrial rubber sheets,as an important sealing material,are widely used in the chemical industry,and their role cannot be underestimated.This article will delve into the significant role of industrial rubber sheets in the sealing of chemical equipment.

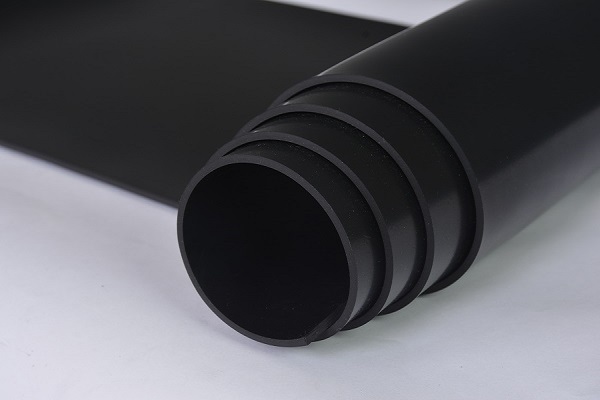

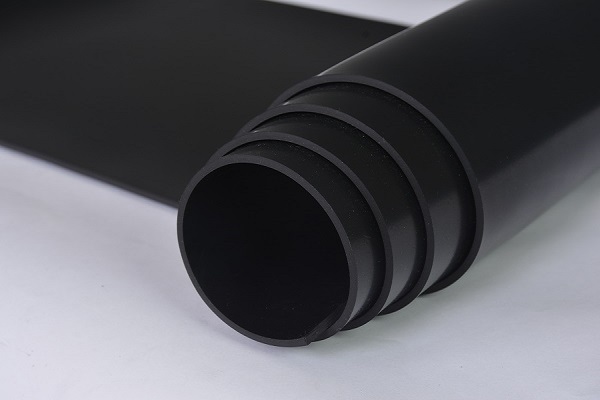

Industrial rubber sheets are specialized vulcanized rubber sheets used in industrial machinery and transportation equipment,with various applications such as rubber pads,sealing gaskets,and buffer plates.Depending on different usage requirements,industrial rubber sheets can be classified into common rubber sheets,acid and alkali resistant rubber sheets,oil resistant rubber sheets,heat resistant rubber sheets,and insulating rubber sheets,among others.This diversity enables industrial rubber sheets to perform excellent sealing effects in various harsh environments.Specifically,the material selection and application of industrial rubber sheets directly affect their sealing performance.For instance,acid and alkali resistant rubber sheets are suitable for highly corrosive environments,while oil resistant rubber sheets are often used in situations involving contact with oils.

>send emails to sales@jingdongrubber.com,get a quote now

In chemical equipment,the role of sealing components is not only to prevent the leakage of liquids,gases,and other materials,but more importantly,to ensure that no harmful substances seep into the production process,thereby safeguarding production safety.Effective sealing can prevent these harmful substances from polluting the surrounding environment,protecting the health of workers and the ecological environment.Additionally,sealing components can regulate and maintain key parameters such as pressure,temperature,and flow rate inside the equipment,directly influencing the stability of the production process and product quality.

Improving the sealing technology of chemical equipment is of great significance for enhancing process efficiency.Good sealing ensures that equipment operates under optimal conditions,thereby increasing production efficiency and reducing operating costs.For example,the application of pressure sealing technology can effectively solve the leakage problems existing in traditional sealing methods,improving the reliability and service life of the equipment.This technology is not only applicable to high-pressure environments but can also adapt to complex working conditions,providing a highly efficient and reliable sealing solution for chemical enterprises.

Industrial rubber sheets play a crucial role in the sealing of chemical equipment.They not only ensure the safety of the production process but also improve process efficiency and reduce operating costs.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.