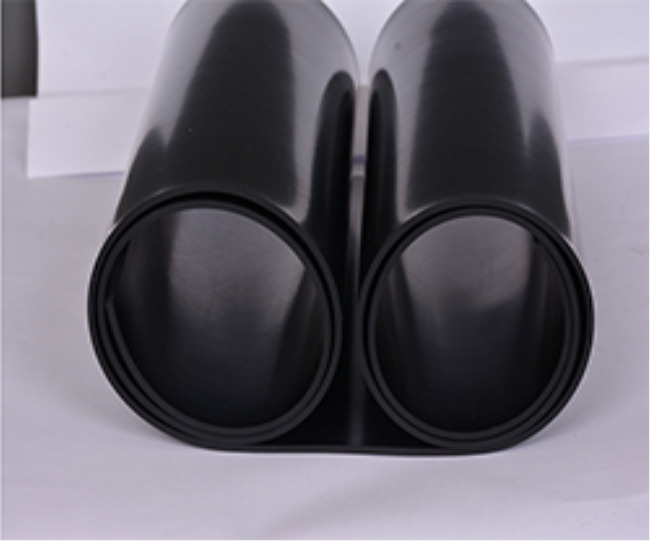

EPDM rubber sheet is a copolymer of ethylene, propylene, and a small amount of non-conjugated diene monomers. What are the uses of EPDM rubber sheet? The uses of EPDM rubber sheet: widely used in automotive parts, building waterproof materials, electrical wire and cable sheaths, heat-resistant rubber hoses, rubber belts, automotive seals, etc. fields.

The properties of EPDM rubber sheet:

Compared with the commonly used general-purpose rubber or specialty rubber, EPDM rubber sheet has the following main performance advantages:

(1) High cost-effectiveness, the density of the raw rubber is only 0.86~0.90 g/cm3, which is the lightest density of the commonly used rubber; and it can be filled in large quantities to reduce the cost of rubber compounds.

(2) Excellent aging resistance, excellent aging resistance to weathering, ozone, sunlight, heat, water, water vapor, ultraviolet rays, and radiation, etc. when used in combination with unsaturated diene rubbers such as NR, SBR, BR, NBR, and CR, EPDM can play the role of a high molecular antioxidant or aging inhibitor.

(3) Excellent resistance to chemicals, resistant to acids, alkalis, detergents, animal and plant oils, alcohols, ketones, etc.; excellent resistance to hot water, boiling water, and water vapor; excellent resistance to polar oils.

(4) Good insulation properties, volume resistivity 1016 Q·cm, breakdown voltage 30~40 MV/m, dielectric constant (1kHz, 20℃) 2.27.

(5) Wide service temperature range, -40~-60℃ in low temperature, can be used for a long time at 130℃ conditions.