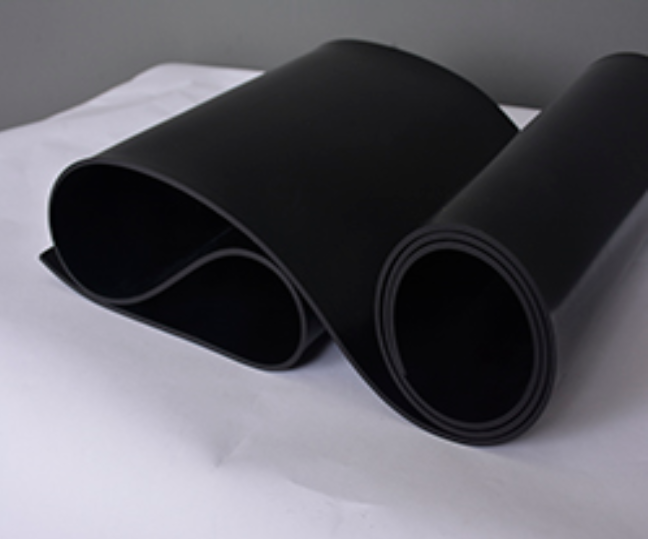

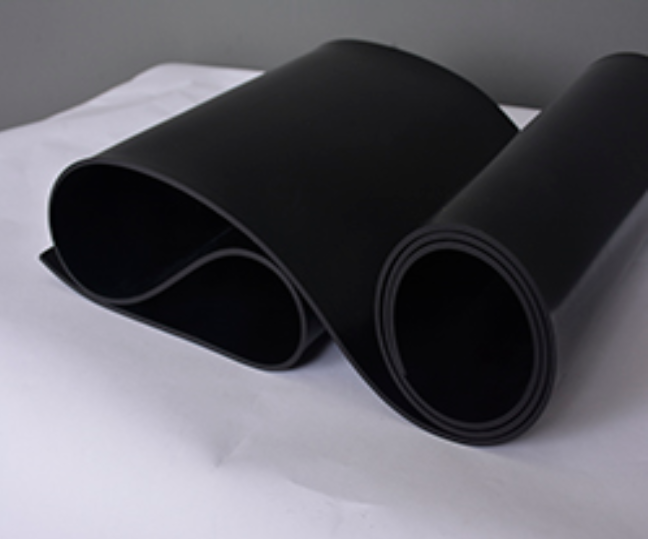

In modern life,rubber products are everywhere.They exist in various forms in our daily lives,such as car tires,seals,and soles of shoes.One very common type of rubber material is black rubber sheet.It is often used in the industrial field,such as mechanical protection and ground skid-resistance.Today,let’s explore the features of black rubber sheet together.

Black rubber sheet is a sheet made of rubber,with a black color.The manufacturing process of this rubber sheet is relatively complex,requiring multiple steps such as rubber refining,molding,and vulcanization to complete.Due to its excellent wear resistance and elasticity,black rubber sheet has widespread applications in many scenarios.

What are the features of black rubber sheet?

First,it has excellent wear resistance.Because rubber has good elasticity and resilience,it is not easily damaged even if subjected to friction and pressure for a long time.

Second,it has good skid-resistance.Rubber itself has a certain degree of anti-skid effect,and by adding certain additives,this property can be further enhanced.

Finally,it has good insulation performance.This makes black rubber sheet have certain application space in the electronics industry.

During use,we may encounter some problems.For example,rubber sheets may show signs of aging,leading to a decline in performance;or they may crack or even break due to external forces during use.These situations may affect the service life and safety of black rubber sheets.

To address these issues,we can take some measures to solve them.For example,choosing high-quality rubber raw materials and production processes can effectively extend the service life of rubber sheets;at the same time,proper use and maintenance are also key.Avoiding exposing rubber sheets to extreme temperatures or corrosive environments can reduce the aging rate;regular inspections and maintenance can detect and repair damage in a timely manner,preventing problems from escalating.