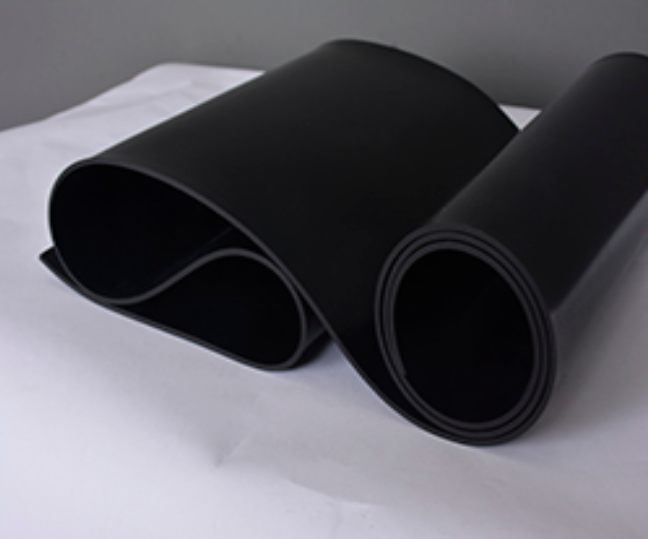

In our daily work and life, we often encounter situations where high temperature resistance is required, such as in the chemical, automotive manufacturing, and aviation industries. In these fields, high temperature rubber sheets are particularly important.

Fluororubber and silicone rubber are the main synthetic materials for high temperature rubber sheets at present, with their maximum operating temperature of 300 degrees Celsius. Their performance in many industrial applications cannot be ignored.

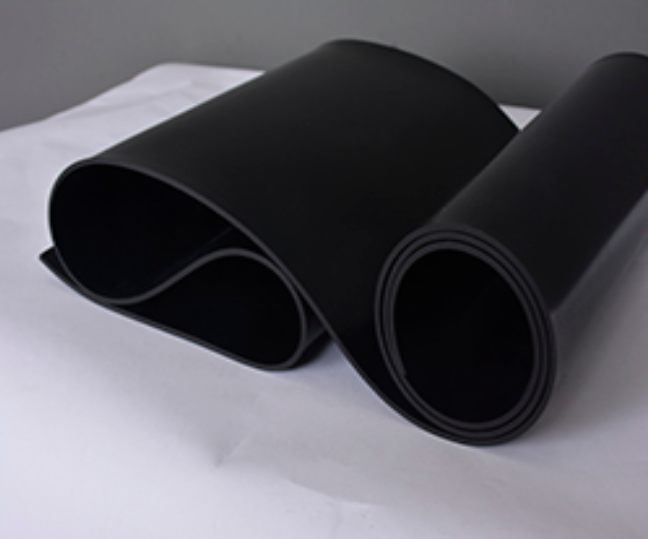

Fluororubber, a synthetic rubber containing fluorine atoms, is renowned for its excellent resistance to chemicals, strong corrosion, and oil. It can work stably at temperatures up to 300°C and is suitable for industrial departments with stringent requirements, such as aviation, chemical industry, and petroleum, where it serves as a sealing material, medium-resistant material, and insulating material. Its temperature resistance is derived from the strong electropositivity of fluorine atoms, which endows the material with excellent thermal stability.

Silicone rubber, on the other hand, is famous for its flexibility in extreme temperatures (from extremely cold to extremely hot). It not only has high temperature resistance but also has good weather resistance, ozone resistance, and light resistance, which makes it widely used in aviation and aerospace, medical devices, and daily consumer goods. Its temperature resistance is due to the high bond energy of the silicon-oxygen bond in its molecular chain, ensuring its stability in high temperature environments.