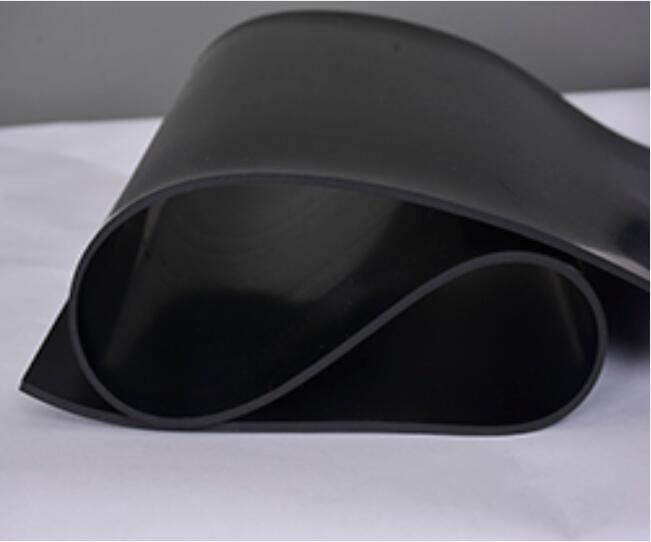

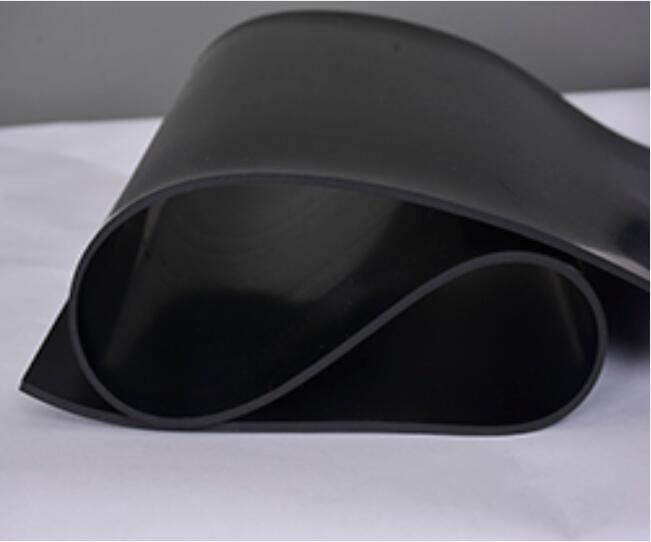

In industry and daily life, rubber sheets are widely used due to their excellent wear resistance, slip resistance, and oil resistance, making them a necessary material in many fields. However, how to efficiently and accurately cut these rubber sheets is a concern for many users. Today, we will explain in detail how 20mm thick rubber sheets should be cut.

Different thicknesses of rubber sheets require different cutting tools. 20mm thick rubber sheet is considered medium thickness, and the commonly used cutting tools include knives, electric cutting machines, and laser cutting machines. Each tool has its advantages and disadvantages, which we will analyze one by one.

1. Knives

Knives are suitable for thinner rubber sheets, but cutting 20mm thick rubber sheet requires some skill and effort. The advantage of using a knife is its flexibility and convenience, allowing operation in various environments. The disadvantage is that the cutting speed is slower, and the technical requirements for the operator are higher, making it easy to produce uneven cuts.

2. Electric Cutting Machines

Electric cutting machines are suitable for thicker rubber sheets, especially 20mm medium-thick boards. The sharp blade of the electric cutting machine can easily penetrate the rubber sheet interior, and the cutting efficiency is high. To reduce dust pollution, it is recommended to use an electric cutting machine with a vacuum cleaner function. It is important to keep the blade perpendicular to the rubber sheet surface to ensure a smooth and even cut.

3. Laser Cutting Machines

Laser cutting machines have the highest precision and are suitable for cutting complex shapes of rubber sheets in bulk. Laser cutting can quickly and accurately complete cutting tasks, but the equipment cost is high and is not suitable for small batches or occasional use requirements.