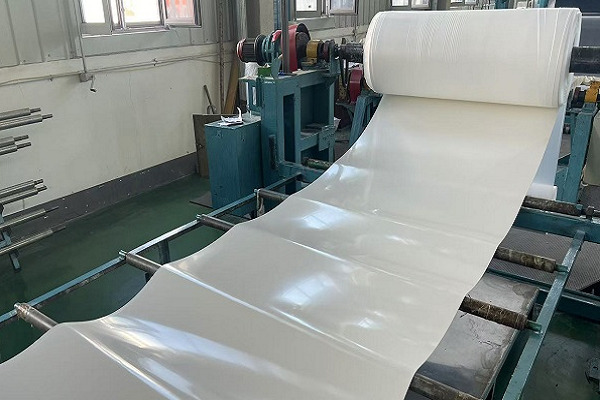

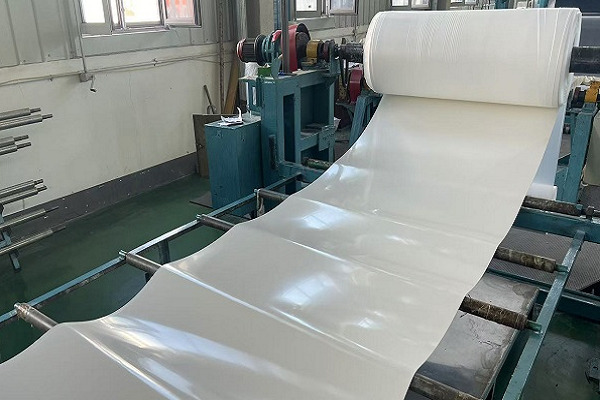

Natural rubber sheets, as an important industrial material, play an indispensable role in many fields due to their unique physical and chemical properties. Understanding their temperature resistance is crucial for their correct use and the expansion of their application range. Let’s delve into the temperature resistance mystery of natural rubber sheets.

I. Overview of Temperature Resistance Characteristics

Generally speaking, natural rubber sheets can withstand temperatures ranging from -60°C to 120°C.

Within this temperature range, they can maintain relatively stable physical and chemical properties, ensuring reliability and durability in various application scenarios.When the temperature drops below -60°C, natural rubber sheets gradually lose their elasticity, becoming stiff and brittle; while when the temperature exceeds 120°C, they begin to soften and deform significantly, and their internal structure is gradually damaged, leading to a decline in performance.

II. Performance at Different Temperatures

Low-temperature environment (-60°C to 0°C): Within this temperature range, natural rubber sheets become hard but still retain some flexibility and elasticity, and can barely maintain basic sealing and buffering functions. For example, in some outdoor equipment in cold regions, natural rubber sheets can work normally at low temperatures, ensuring the stable operation of the equipment. However, as the temperature decreases, the elastic recovery speed slows down significantly, and it takes longer to return to the original state.

Normal-temperature environment (0°C to 40°C): This is the temperature range where natural rubber sheets perform best. Under these conditions, they have excellent elasticity, tensile strength, and wear resistance, and can well adapt to various mechanical movements and vibrations. They are widely used in automotive parts, building seals, and other fields. For instance, the door and window seals of cars can closely adhere to the body at normal temperatures, effectively blocking external noise, dust, and moisture.

High-temperature environment (40°C to 120°C): When the temperature rises above 40°C, natural rubber sheets gradually soften, but their performance can still meet some general requirements. However, as the temperature further increases to approach 120°C, they rapidly soften, and their strength and hardness significantly decrease. In some high-temperature working conditions, such as near engine and other heat-generating components, special high-temperature resistant rubber materials or modified natural rubber sheets are needed to improve their high-temperature resistance.

>send emails to sales@jingdongrubber.com,get a quote now

III. Mechanism of Temperature’s Impact on Performance

Temperature changes have a significant impact on the molecular structure and physical properties of natural rubber sheets. At low temperatures, the activity of molecular chains weakens, and the interaction between molecules increases, causing the material to become hard and brittle; while at high temperatures, molecular chains gain more energy, their activity intensifies, and the distance between molecules increases, making the material softer. In addition, prolonged exposure to high temperatures will accelerate the aging process of rubber, causing molecular chain breakage and cross-linking reactions, further reducing its performance.

IV. Application and Limitations of Temperature Resistance

Based on their temperature resistance characteristics, natural rubber sheets have important applications in many fields.

In the automotive industry, they are used to manufacture tires, shock absorbers, seals, and other components, providing reliable performance in different seasons and driving conditions.

In the construction industry, they are used as sealing materials for doors and windows, pipe connections, etc., to prevent wind, rain, and air infiltration.

However, the limitations of their temperature resistance range also require caution in their use in some special high-temperature or low-temperature environments or the search for alternative materials. For example, in high-temperature industrial fields such as aerospace and metallurgy, special rubber materials with better high-temperature resistance, such as silicone rubber and fluorine rubber, are usually used to meet the harsh working conditions.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.