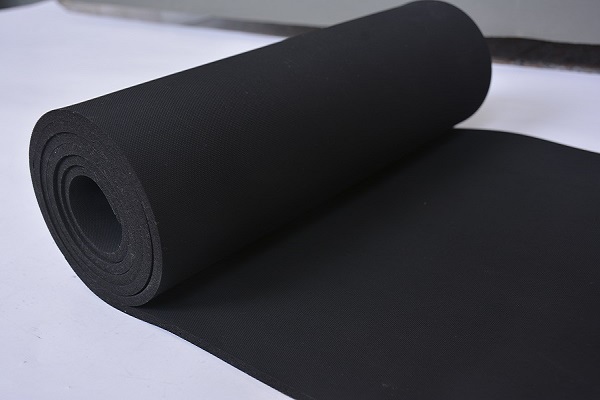

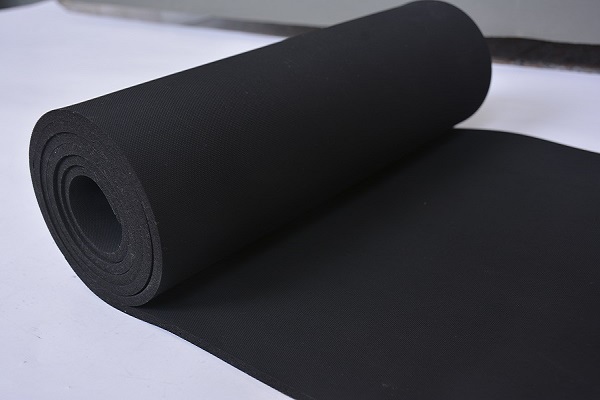

In the fields of industrial manufacturing and construction,rubber sheets are a common and important material.Their application range is extensive,from sealing,shock absorption to protection,all of which cannot do without this durable and multi-functional material.And the 10mm thick rubber sheet,due to its moderate thickness and excellent physical properties,has attracted much attention.So,what exactly is the weight of a 10mm thick rubber sheet?

To determine the weight of a 10mm thick rubber sheet,it is first necessary to understand the density of the rubber sheet.The density of rubber sheets generally ranges from 1.1 to 1.7 grams per cubic centimeter.This range of variation is mainly due to the different materials of the rubber sheets,such as styrene-butadiene rubber,chloroprene rubber,ethylene propylene diene monomer rubber and nitrile rubber,etc.,each with slightly different densities.In addition,the type of filler also affects the overall density of the rubber sheet.

Taking a common industrial rubber sheet as an example,assuming we use a rubber material with a density of 1.3 grams per cubic centimeter to calculate the unit area weight of a 10mm thick rubber sheet.10mm equals 0.01 meters,so the volume of each square meter of rubber sheet is 0.01 cubic meters,that is,10,000 cubic centimeters.From this,we can calculate the weight of each square meter of rubber sheet:

10,000 cubic centimeters×1.3 grams per cubic centimeter=13,000 grams=13kg

Of course,this is only an approximate value,and the actual weight may vary slightly due to specific rubber formulas and changes in production conditions.

In addition to density,factors affecting the weight of a 10mm thick rubber sheet also include its size and shape.

For example,rubber sheets of the same thickness but different areas will naturally have different weights.A standard industrial rubber sheet usually has specific size specifications,such as length and width,but it can also be cut and customized according to usage requirements.

The manufacturing process of rubber sheets also has a significant impact on their weight.

Generally,rubber sheets are made through a series of processes such as mixing,calendering and vulcanization.During these processes,factors such as temperature,pressure and time all affect the final density and weight of the rubber sheet.For example,high-temperature vulcanization can make the rubber molecular structure more compact,thereby slightly increasing its density.

The application of rubber sheets is also an important factor.

According to different application scenarios,such as sealing,shock absorption or floor laying,the formulas and processes of rubber sheets may vary.For example,rubber sheets used for sealing may pay more attention to their elasticity and chemical resistance,while rubber sheets used for floor laying may need better wear resistance and compressive resistance.These characteristics also affect the weight of the rubber sheet to a certain extent.

The weight of a 10mm thick rubber sheet is influenced by multiple factors,including the density,size,shape and manufacturing process of the rubber.

Through reasonable calculation and selection,you can find the rubber sheet product that best meets your needs.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, Neoprene Rubber Sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.