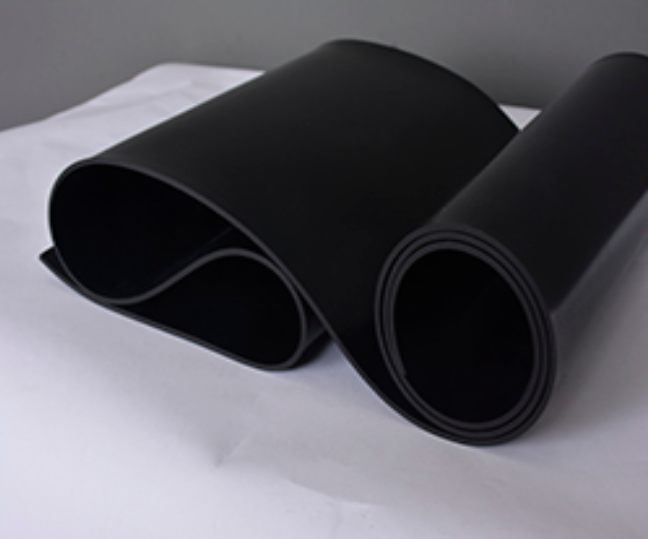

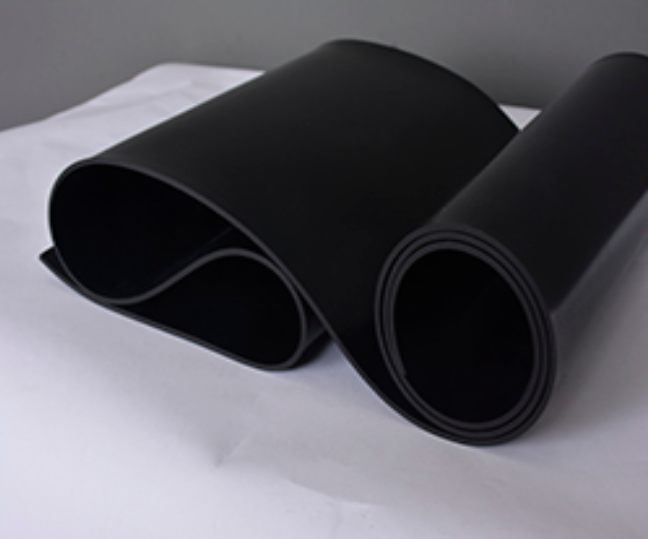

In this era of rapid technological advancement, viton rubber sheets are gaining attention for their outstanding performance. They are not only resistant to oil and high temperatures, but also resistant to chemical corrosion, making them widely used in fields such as aviation, aerospace, automotive, and petrochemical. So, what exactly is viton rubber sheet?

1. The main components of viton rubber sheet

The basic raw material for viton rubber sheet is viton rubber compound, on which additional components such as sulfurizing agents like bisphenol AF or bisphenol S, and accelerators like dimethylaniline are added. These substances work together to form a stable three-dimensional network structure during the vulcanization process, giving the viton rubber sheet excellent physical and chemical properties.

2. The manufacturing process of viton rubber sheet

1.1 Mixing

The viton rubber compound, sulfurizing agents, accelerators, fillers, etc. are added to a mixer in a certain proportion, and mixed at a certain temperature to achieve mixing. The key to this step is to ensure that the raw materials are evenly mixed. The temperature and time during mixing must be strictly controlled to avoid overheating or over-vulcanization of the rubber, and to ensure the quality of the mixture. After mixing, the rubber will be thinly rolled on an open mixer to further homogenize.

1.2 Vulcanization

After the mixed rubber is cut into sheets of a certain shape and size, it is placed in a mold and vulcanized at a certain temperature and pressure. It is crucial to control the temperature, pressure, and time during the vulcanization process, as it directly affects the degree of vulcanization and physical properties of the viton rubber.

1.3 Deburring and cleaning

After the vulcanization is completed, the products are taken out for post-processing, including deburring and cleaning.

By precisely controlling the parameters of each step and paying attention to safety and environmental protection, high-performance viton rubber sheets can be prepared, providing important material support for many fields.