稳定垫的绝缘效果如何

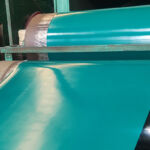

在牲畜行业,the quality of the cowshed environment plays a crucial role in the health and production performance of cattle.Temperature control is particularly important.As a new type of flooring material for cowsheds,stable mats have attracted much attention for their insulation properties.So,how effective are the insulation properties of stable mats?And how do they function to insulate?Let’s find out. From…