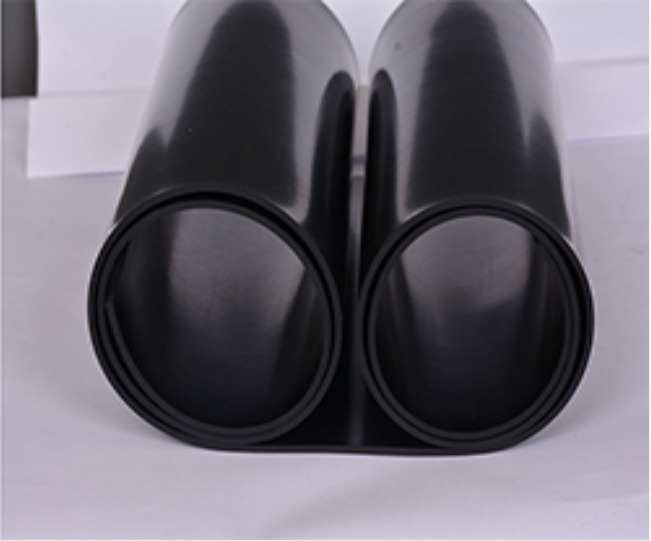

EPDM rubber is a high-performance synthetic rubber, mainly composed of ethylene, propylene and a small amount of non-conjugated diene.The following are its performance:

High temperature stability. EPDM rubber has excellent heat resistance, long-term use temperature of 120 DEG C to 170 DEG C, short-term use temperature of 200 DEG C.

Aging resistance. It has good aging resistance, including ozone resistance, weather resistance, etc., keep long-term use without discoloration.

Corrosion resistance. EPDM rubber has good resistance to polar chemicals such as acid and alkali, alcohol, oxidant, etc., but not resistant to fatty hydrocarbons and aromatic hydrocarbons, poor stability in gasoline.

Elasticity. EPDM rubber has good elasticity, can maintain stable performance in complex stress environment.

Physical properties. Its tensile strength and elastic modulus are relatively stable physical properties, with good mechanical properties.

Electrical insulation. EPDM rubber also has good electrical insulation performance, suitable for electricity, communications and other fields.

Steam resistance. It has excellent steam resistance, and can still maintain at high temperatures.

Low density high filling. EPDM rubber has low density, can be filled with oil and added fillers in large quantities, helping to reduce the cost of rubber products.

EPDM is widely used in automotive parts, building waterproof materials, wire and cable sheath, heat-resistant hose, adhesive tape, automotive seals and other fields. It is also suitable for making tires, industrial belts, sealing products, hose and other industrial products, as well as sports equipment and recreational rest areas.