La principal diferencia entre el caucho sintético y el caucho natural radica en su composición., actuación, aplicaciones, y propiedades físicas.

La composición es diferente: El caucho sintético es un polímero elástico sintetizado artificialmente., también conocido como elastómero sintético, que es uno de los tres materiales sintéticos, con un volumen de producción sólo superado por la resina sintética (o plastico) y fibras sintéticas. Caucho natural, por otro lado, es un compuesto natural de alto peso molecular con cis-1,4-poliisopreno como componente principal, con 91% a 94% siendo hidrocarburos de caucho (cis-1,4-poliisopreno) y el resto son proteínas, ácidos grasos, ceniza, y azucares, entre otras sustancias distintas del caucho.

El rendimiento es diferente: El caucho natural tiene alta elasticidad y buen aislamiento eléctrico a temperatura ambiente., pero es fuerte en resistencia a los álcalis pero no a los ácidos fuertes. caucho sintético, aunque su rendimiento es relativamente inferior, todavía tiene alta elasticidad, aislamiento, resistencia al aceite, y resistencia a alta temperatura, y es ampliamente utilizado.

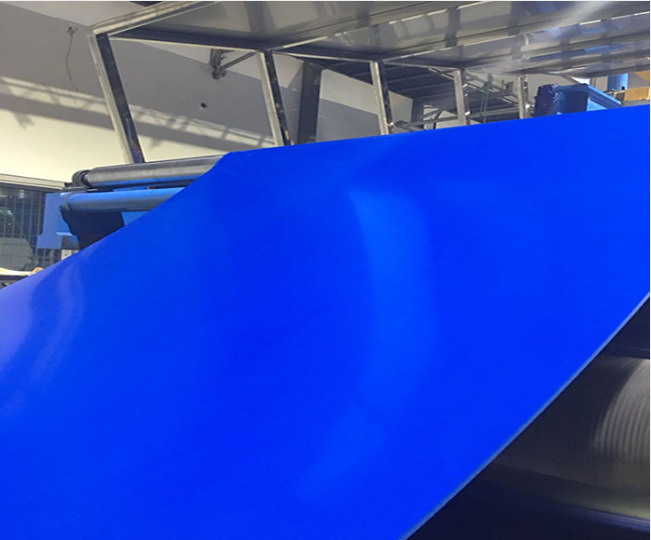

Las aplicaciones son diferentes: El caucho sintético se utiliza ampliamente en la industria., agricultura, defensa, transporte, y la vida diaria. Caucho natural, por otro lado, Es muy utilizado en botas de lluvia., bolsas de agua caliente, bandas elásticas, cintas transportadoras, cinturones de transporte, guantes resistentes a los ácidos, e incluso productos de alta tecnología como cohetes, satélites artificiales, y nave espacial.

Las propiedades físicas son diferentes.: Las propiedades del caucho sintético varían según el monómero., Sólo unas pocas variedades tienen propiedades similares a las del caucho natural.. Algunos cauchos sintéticos tienen mejor resistencia al calor., resistencia al desgaste, resistencia al envejecimiento, resistencia a la corrosión, o resistencia al aceite que el caucho natural. El caucho natural tiene alta elasticidad y ligera plasticidad a temperaturas normales., Cristaliza y endurece a bajas temperaturas., Tiene buena resistencia a los álcalis pero no fuerte al ácido..