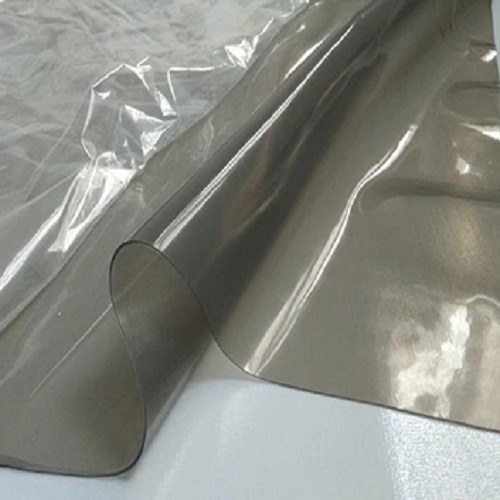

Transparent silicone sheets, as an important material in the field of science and industry, are increasingly used in a wide range of applications. From medical instruments to electronic products, to various items in daily life, transparent silicone sheets are widely used due to their unique physical and chemical properties.

1. Basic characteristics of transparent silicone sheets

Silicone, Como material de polímero de alto rendimiento, has excellent transparency, good flexibility, and very high heat resistance.

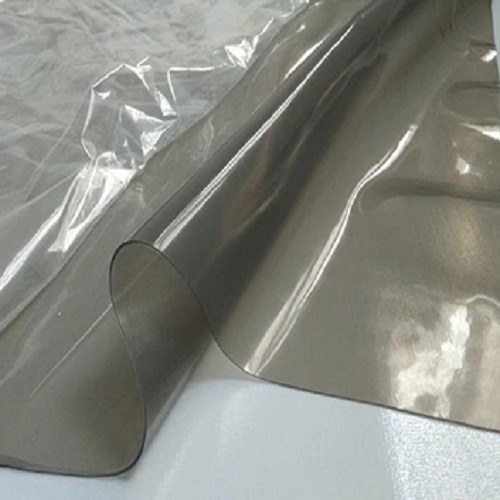

The hardness of transparent silicone sheets is usually measured using the Shore C scale, while specific applications such as heat conductive interface materials require a certain level of hardness (Shore C30±5) to ensure the stability and effectiveness of the material in conducting heat.

2. Applications of transparent silicone sheets

En la industria electrónica, transparent silicone sheets are often used as part of a heat dissipation solution. Por ejemplo, filling heat-conducting silicone pads between heat-generating chips and heat-dissipating components can effectively transfer heat from the heat source to the heat-dissipating components, keeping the device’s temperature within a safe range. This application not only requires the silicone sheet to have good heat conductivity, but also requires it to have low volatility to avoid oil stains caused by possible pollution problems during long-term high-temperature operation.

In addition to applications in electronic devices, transparent silicone sheets are widely used in security products, dispositivos médicos, y otros campos. With the advancement of technology, there is an increasing demand for high-definition video surveillance products, which directly drives the need for more efficient heat dissipation materials. En este caso, transparent silicone sheets, with their excellent thermal conductivity and stability, have become one of the key materials to enhance product performance.