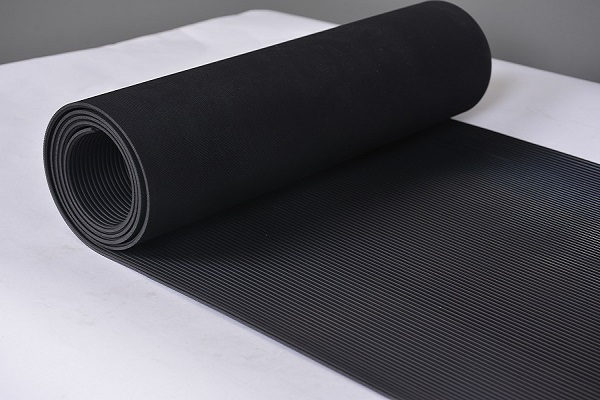

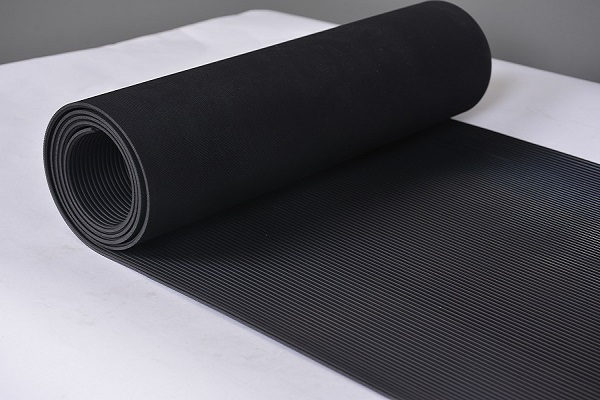

When rubber mats industrial are placed in outdoor environments,people often worry about whether they will deteriorate over time.This issue is related to the safety and cost-effectiveness of many applications,such as supporting and buffering in building structures,protecting the foundations of mechanical equipment,and reducing vibration and noise in various facilities.To explore their durability,a comprehensive analysis from multiple aspects such as material properties,aging factors,and actual performance is required.

Different types of rubber materials provide diverse options to cope with complex and changing environments.

Natural rubber is known for its excellent elasticity and high tensile strength,making it suitable for applications with strict requirements for rebound performance;caucho de nitrilo,with its outstanding oil resistance,is often used as a vibration isolation medium between mechanical components that are prone to contact with oils;caucho de cloropreno,with its good weather resistance and flame retardancy,shows advantages in outdoor environments;monómero de etileno propileno dieneno(EPDM)goma,with its excellent anti-aging ability and wide temperature adaptability,is widely used in building sealing and the automotive industry.The differentiated performance of these materials enables engineers to precisely match the most suitable solution based on specific working conditions.

Even if high-quality raw materials are selected,the harsh natural conditions outdoors still pose continuous challenges to rubber pads.

Temperature fluctuations are the primary test-in the scorching summer,high temperatures accelerate the movement rate of molecular chains,promoting intense oxidation reactions,causing the material to gradually harden and become brittle;in the freezing winter,low temperatures may lead to material shrinkage and cracking.

Ultraviolet rays in sunlight act like invisible knives,gradually cutting into the molecular structure of rubber,making the surface rough,the color dull,y en casos severos,causing cracking.Oxygen and ozone in the air are also destructive:oxygen erodes polymer chains through free radical chain reactions,while ozone,due to its higher chemical activity,can form deep cracks perpendicular to the direction of stress(i.e.,”craqueo de ozono”)at stressed areas.In addition,issues such as water penetration from rain and wind,adhesion of acidic and alkaline pollutants,and microbial growth should not be ignored.

> Envíe correos electrónicos a sales@jingdongrubber.com,Obtenga una cotización ahora

Whether a rubber pad has significantly aged can be determined through visual inspection.

If the surface is covered with fine lines or obvious cracks,the color is abnormally darkened or faded and loses its luster,feels harder but less flexible when touched,or becomes sticky and easily attracts dust and impurities,these are all typical signs of material performance degradation.At this point,the remaining service life should be evaluated as soon as possible,and replacement should be carried out in a timely manner if necessary to avoid safety hazards.

It is worth noting that advancements in modern production processes have effectively extended the service life of products.

Por ejemplo,composite rubber products designed with special formulas combine the advantages of multiple polymer materials,maintaining the integrity of basic functions while enhancing resistance to environmental erosion.Reasonable structural design can also disperse stress concentration points and delay the development of fatigue damage.Regular cleaning and maintenance,as well as avoiding scratches on the surface from sharp objects,are also helpful in maintaining the good condition of rubber pads.

En aplicaciones prácticas,many cases have proven that high-quality rubber pads can have a long service life in outdoor environments.

Corrosion-resistant rubber gaskets in chemical enterprises can stably support equipment operation in strong acid and alkali environments for many years;insulating rubber bases in the power industry can maintain reliable electrical performance after long-term exposure to ultraviolet rays;vibration-reducing rubber components in transportation facilities can still play a buffering role after experiencing seasonal temperature changes.Of course,the specific service life also needs to be comprehensively considered based on local climate characteristics,frecuencia de uso,and other factors.

En general,esteras de goma industriales do face aging risks when used outdoors,but through scientific material selection,optimized design,and proper maintenance,they can achieve long-term stable performance.For users,regularly checking the status of materials and timely upgrading and replacing them as needed is the key to ensuring the safe and reliable operation of the system.

Jingdong caucho Co., Limitado. es un fabricante profesional de láminas de caucho, producir láminas de caucho de silicona, lámina de caucho natural, lámina de caucho flúor, hoja de goma de neopreno, lámina de caucho aislante,láminas de caucho EPDM, láminas de caucho resistentes al aceite, láminas de goma antiestáticas, láminas de caucho retardantes de llama, láminas de caucho conductoras, láminas de goma antideslizantes, y esteras de establo, etc.. con 40 años de experiencia en la industria, son populares tanto en casa como en el extranjero. Si necesitas alguno de nuestros productos,por favor envíe correos electrónicos a ventas@jingdongrubber.com.